This fall, the world’s tallest modular hotel—a 26-story, 360-foot-tall building that will be branded AC Hotel New York NoMad when it opens late next year—will start stacking prefabricated and prefurnished guestrooms for assembly in New York City.

This is one of 50 projects that Marriott International, since launching its pilot modular initiative in 2015, has incorporated prefab guestrooms or bathrooms.

In May, the hotelier developed specific modular concepts for its Fairfield Inn, Courtyard, SpringHill Suites, TownePlace, and Four Points by Sheraton brands. It deploys modular construction for its AC Hotels brand, and later this year will start stacking its first modular-built Moxy hotel in the U.S., in Oakland, Calif.

Jennifer Abuzeid, Senior Director–Global Design Strategies, says that Marriott began exploring modular construction in response to its post-recession pipeline expanding. (That pipeline currently exceeds 4,000 hotels for all of its brands.) Couple that with a dicey labor market, which put a major crimp in scheduling: a 120- to 150-room Courtyard hotel was taking 21 months to complete, compared to 12 months prerecession, says Abuzeid.

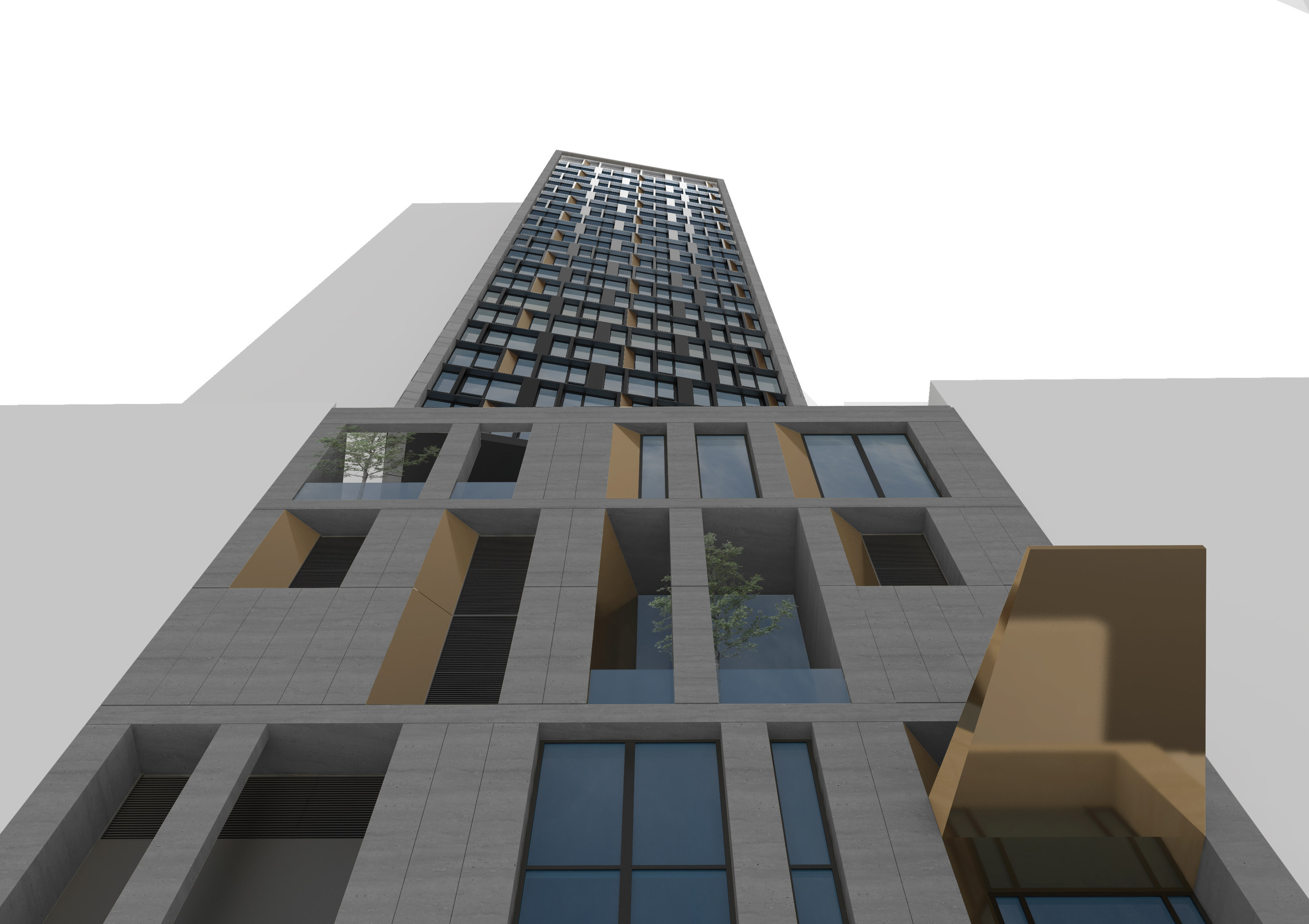

At 26 stories and 360 feet, Marriott International's AC Hotel New York NoMad will be the world’s tallest modular hotel when it opens next year. Besides finished, painted walls, each module will contain a fully outfitted guest room, with beds, sheets, pillows, flooring, even toiletries, according to architect Danny Forster & Architecture. Associate architect: Epstein. Photo courtesy Marriott Intl. and Danny Forster & Architecture

At 26 stories and 360 feet, Marriott International's AC Hotel New York NoMad will be the world’s tallest modular hotel when it opens next year. Besides finished, painted walls, each module will contain a fully outfitted guest room, with beds, sheets, pillows, flooring, even toiletries, according to architect Danny Forster & Architecture. Associate architect: Epstein. Photo courtesy Marriott Intl. and Danny Forster & Architecture

Abuzeid admits that Marriott’s embrace of modular construction has been a learning curve. Finding enough module manufacturers to meet its needs continues to be a battle. Skystone Group is the General Contractor and Modular Manufacturer on this New York AC Hotel project. It manufactures the modules using a Europe-based supply chain: DMD Modular, STP Elbud, and Aluprof are the main subcontractors contributing to the modular scope, according to Greg Thompson, Chief Financial Officer for Skystone Group.*

But the “great benefits” of modular, she says, include consistent product quality, eliminating change orders, and reducing punch lists and jobsite waste.

Marriott has an in-house design team that sets the prototype parameters for its brands. Its franchisees hire the building teams and module suppliers to construct the hotels. This year, Marriott began offering incentives to developers that leverage prefabrication for guestroom construction.

SEE ALSO: Mace Group built working factories on top of under-construction skyscrapers

Abuzeid estimates that modular production and assembly shave anywhere from three to eight months off of a hotel’s construction time. She adds that the franchisee that built the 354-key, dual-branded Courtyard and TownePlace Suites by Marriott property in Hawthorne, Calif., may have reduced its construction period by a year “in a very difficult real estate market.”

Abuzeid estimates that 40% of Marriott’s Select brands in North America, which account for more than two-fifths of its backlog, has the potential for modular construction.

“We consider modular design and construction very important to our expansion strategy in North America, where it’s currently not as commonly leveraged as in other parts of the world,” says Eric Jacobs, Marriott International’s Chief Development Officer for Marriott Select Service and Extended Stay Brands in North America.

*Information about Skystone Group's role Marriott's AC Hotel project was added after this story was originally posted.

Marriott's Jennifer Abuzeid, Senior Director–Global Design Strategies, estimates that modular production and assembly shave anywhere from three to eight months off of a hotel’s construction time. She adds that the franchisee that built the 354-key, dual-branded Courtyard and TownePlace Suites by Marriott property in Hawthorne, Calif., may have reduced its construction period by a year “in a very difficult real estate market.” Photo: Marriott

Marriott's Jennifer Abuzeid, Senior Director–Global Design Strategies, estimates that modular production and assembly shave anywhere from three to eight months off of a hotel’s construction time. She adds that the franchisee that built the 354-key, dual-branded Courtyard and TownePlace Suites by Marriott property in Hawthorne, Calif., may have reduced its construction period by a year “in a very difficult real estate market.” Photo: Marriott

Related Stories

AEC Innovators | Apr 15, 2024

3 ways the most innovative companies work differently

Gensler’s pre-pandemic workplace research reinforced that great workplace design drives creativity and innovation. Using six performance indicators, we're able to view workers’ perceptions of the quality of innovation, creativity, and leadership in an employee’s organization.

Sustainability | Mar 21, 2024

World’s first TRUE-certified building project completed in California

GENESIS Marina, an expansive laboratory and office campus in Brisbane, Calif., is the world’s first Total Resource Use and Efficiency (TRUE)-certified construction endeavor. The certification recognizes projects that achieve outstanding levels of resource efficiency through waste reduction, reuse, and recycling practices.

AEC Innovators | Feb 28, 2024

How Suffolk Construction identifies ConTech and PropTech startups for investment, adoption

Contractor giant Suffolk Construction has invested in 27 ConTech and PropTech companies since 2019 through its Suffolk Technologies venture capital firm. Parker Mundt, Suffolk Technologies’ Vice President–Platforms, recently spoke with Building Design+Construction about his company’s investment strategy.

MFPRO+ Special Reports | Feb 22, 2024

Crystal Lagoons: A deep dive into real estate's most extreme guest amenity

These year-round, manmade, crystal clear blue lagoons offer a groundbreaking technology with immense potential to redefine the concept of water amenities. However, navigating regulatory challenges and ensuring long-term sustainability are crucial to success with Crystal Lagoons.

AEC Tech | Feb 20, 2024

AI for construction: What kind of tool can artificial intelligence become for AEC teams?

Avoiding the hype and gathering good data are half the battle toward making artificial intelligence tools useful for performing design, operational, and jobsite tasks.

Sustainability | Nov 1, 2023

Researchers create building air leakage detection system using a camera in real time

Researchers at the U.S. Department of Energy’s Oak Ridge National Laboratory have developed a system that uses a camera to detect air leakage from buildings in real time.

Contractors | Aug 14, 2023

Fast-tracking construction projects offers both risk and reward

Understanding both the rewards and risk of fast-tracking a project can help owners, architects, engineers, and contractors maximize the benefits of this strategy and can bring great reward on all fronts when managed properly.

Resiliency | Aug 7, 2023

Creative ways cities are seeking to beat urban heat gain

As temperatures in many areas hit record highs this summer, cities around the world are turning to creative solutions to cope with the heat. Here are several creative ways cities are seeking to beat urban heat gain.

Digital Twin | Jul 31, 2023

Creating the foundation for a Digital Twin

Aligning the BIM model with the owner’s asset management system is the crucial first step in creating a Digital Twin. By following these guidelines, organizations can harness the power of Digital Twins to optimize facility management, maintenance planning, and decision-making throughout the building’s lifecycle.

AEC Innovators | Jun 15, 2023

Rogers-O'Brien Construction pilots wearables to reduce heat-related injuries on jobsites

Rogers-O'Brien Construction (RO) has launched a pilot program utilizing SafeGuard, a safety-as-a-service platform for real-time health and safety risk assessment. Non-invasive wearables connected to SafeGuard continuously monitor personnel to prevent heat exhaustion on jobsites, reducing the risk of related injuries. RO is the first general contractor to pilot this program.