Albuquerque BioPark Penguin Chill Exhibit

Albuquerque

Best Project

Owner/Developer: City of Albuquerque

Lead Design Firm: Van H. Gilbert Architects

General Contractor: HB Construction

Structural Engineer: Chavez-Grieves

Civil Engineer: Isaacson & Arfman

MEP Engineer: Bridgers & Paxton

Life Support Engineering: Alvine and Associates

Subcontractors: Andreoloa Terraza; Coreslab; Orcom; Apic Solutions; Edgewood Glass; Pace Metals; Beaty Masonry; Empire Builders; Question Roofing; F&R; Ray’s Flooring; Hammerhead International; Reynolds Polymer Technology; CMC Rebar; Kaufman Fire Protection; Seal Co.; Contreras; Millers Insulation; TLC

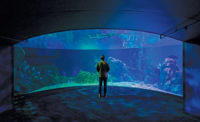

The Penguin Chill Exhibit at Albuquerque BioPark Zoo is home to 32 different species of penguins. Completed in May, the 14,000-sq-ft building features a 75,000-gallon water tank with depths of 5 ft to 12 ft and offers above-ground and underwater viewing areas, allowing guests to watch the birds swim. Designed to emulate conditions in the Arctic, the penguins’ native habitat, the exhibit features handcrafted rocks and even snow falling from the ceiling. Also included nearby is a large, interactive educational area, a snack bar and an outdoor deck overlooking the zoo’s main park.

Over the course of this 10-month design-bid-build project, the team used a combination of Revit, Autodesk BIM 360 Glue and Field to coordinate building designs, procedures and schedules. At the site, the team leveraged everything from LIDAR and UAV scanning to a total robotic station.

“The breadth of tools used and the buy-in from all parties was really remarkable,” says Bruce Gunderson, president of BIM consulting services at HB Construction.

The team uncovered existing utilities by using ground-penetrating radar to scan the site before excavation began. In response, crews excavated the area 5 ft below the anticipated grading level to avoid disruptions from drilling. Utilities were modeled virtually for underground coordination drawings, then scanned again with work-in-place utilities before backfilling. Total robotic stations helped the team create a virtual model with a point layout system, which allowed for prefabricated hollow-core concrete slabs to fit the unique curve of the ceiling.

Given the jobsite’s location in an operational zoo, surrounded by wild animals and visitors, the team put special protocols in place, including training for evacuation to a safe zone if an animal escaped.

Other zoo-related protocols included not stopping or parking behind animal exhibits and limiting loud noises on site. When the team was working on the roof, workers had to make their tie-offs visible to zoo visitors to limit concerns. When crews worked over the empty tank with a 15-ft drop, a strict tie-off protocol was in place. Workers wore life jackets while the tank was full of water.

Back to "ENR Southwest's 2019 Best Projects: Innovation, Skillful Renovations Lauded"

Post a comment to this article

Report Abusive Comment