With a new leader, a $4.5-billion capital program and now a green light to pursue a major rail support facility, the Port of Long Beach is rebounding from a major tenant’s bankruptcy and looking to fulfill a zero-emissions goal.

In January, the Long Beach Board of Harbor Commissioners approved the Pier B On-Dock Rail Support Facility, a project that will enable shipping containers to be placed directly on trains at the marine terminals. Currently, the ability to build long trains is limited due to the lack of adequate yard tracks and the configuration of mainline tracks. On-dock rail usage in the port was 24% in 2017.

The next steps include the board’s consideration of a baseline budget for the project after preliminary designs are completed over the coming months.

The project is the latest milestone in a flurry of construction work at the port, including the new $1.5-billion Gerald Desmond Bridge, where crews last December topped off two 515-ft-tall towers.

The new bridge, along with the rest of the port’s modernization projects, will enable supersize cargo ships to call at the port, which can currently handle vessels carrying up to 14,000 TEUs (20-ft equivalent unit containers), says Mario Cordero, the port’s executive director.

“Our terminals will be able to receive 22,000-TEU vessels.”

– Mario Cordero, POLB executive director

“In a couple more years, our terminals will be able to receive 22,000-TEU vessels,” Cordero says.

Cordero, a former Long Beach harbor commissioner and onetime head of the Federal Maritime Commission, took the helm last spring as the port struggled with the 2016 bankruptcy of its largest tenant, Hanjin Shipping. The port experienced an 8.2% drop in cargo imports that year.

But Mediterranean Shipping Co. took over the container lease, and the port saw an 11% increase in 2017, with 7.5 million TEUs. “That is the highest total in our 107-year history,” he says.

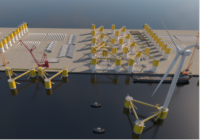

The Middle Harbor Redevelopment Program, which launched in 2011, is now in its third and final stage. The first two phases of the nine-year, $1.6-billion program involved dredging wider and deeper channels, wharf construction, backlands development, shore-to-ship power, expansion of on-dock railyard facilities, construction of a fully automated 304-acre container terminal and a new 4,200-ft concrete pile-supported wharf with three deepwater berths that support 18 shore-to-ship gantry cranes.

“There are not many ports in the world that can support 18,000-TEU ships,” says Craig Halvorson, operations leader with Arcadis, which provided construction management services for Phase 1 and is a consultant on the Desmond Bridge. “The Middle Harbor program will create that kind of facility.”

The new terminal features the first-ever use of automated guided vehicles at a U.S. port, say port officials. Guided by transponders in the asphalt, the battery-powered vehicles transport containers from ships to storage areas and can recharge themselves.

The third phase entails renovating an existing container terminal and connecting it to the new one with 40 acres of fill and expanding the on-dock rail yard from 10,000 linear ft to 66,000.

Cordero adds that the port aims to reduce greenhouse gases by 40% in 2030 and 80% by 2050 with an ultimate goal of zero emissions. The plan includes increased use of on-dock rail. “We have a goal of raising our on-dock volumes to at least 35% of our shipments,” says Cordero. The greenlighted rail support facility is key to that goal.

Post a comment to this article

Report Abusive Comment