As the donations pour in to aid the reconstruction efforts of the fire-damaged Notre Dame cathedral in Paris and the French government opens the question of whether to rebuild the 850-year-old landmark as it was, engineers, architects and contractors can turn to 3D laser scan data of Notre Dame to help with the government’s pledge to reconstruct the building within five years.

“Having laser scans [of Notre Dame] is critical in shortening the reconstruction time frame,” says John Russo, president and CEO of Architectural Resource Consultants and president of the U.S. Institute of Building Documentation. “If you don’t have that data, where do you go? You are going back to hand drawings that may not exist and those are going to be two-dimensional and not have as much information. As far as answering questions and shortcutting the timeline on doing the repair work, 3D scans are going to shave an incredible amount of time off.”

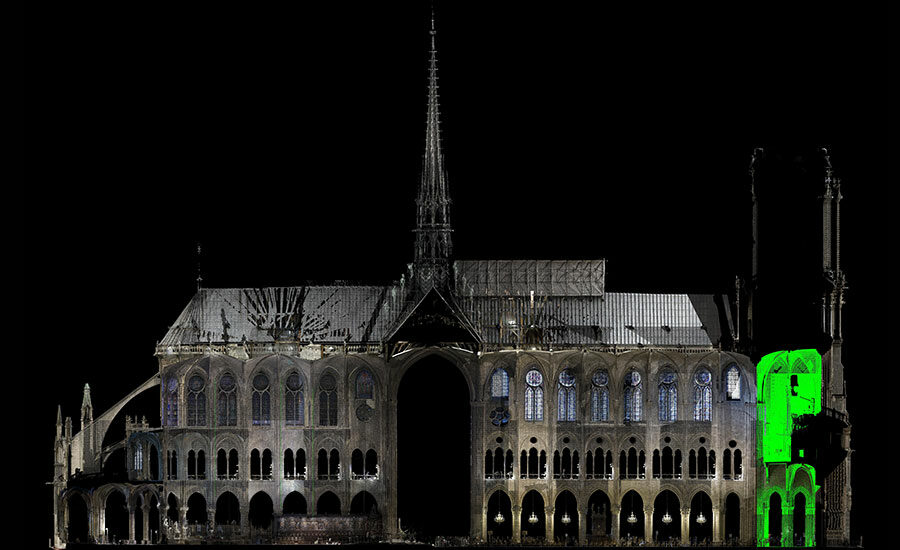

The late Andrew Tallon, an art history professor at Vassar College in upstate New York, worked with colleagues in 2015 finish a laser scan process at Notre Dame. Using a tripod-mounted Leica ScanStation C10 laser, Tallon spent five days mapping Notre Dame. Combining scans with high-resolution panoramic photos, Tallon added color to his data, giving potential project engineers and contractors an even greater amount of information.

The Notre Dame project from Tallon, which saw him reposition the scanner 50 times, created more than one billion points of data — a high-resolution digital blueprint of Notre Dame.

“Laser scanning can measure places and surfaces with tremendous accuracy that you could never hope to get to in person, such as the curvature of a flying buttress,” says Michael Davis, chair of architectural studies, professor of art history at Mount Holyoke College in Massachusetts, and a former colleague of Tallon’s. “I think the laser scanning offers a really useful document of the state of the structure. You can see how it is behaving, if it is out of plumb, if everything is where it should be.

“It creates or documents with great precision the building as it stands.”

Russo says this 3D image of the space contains all the dimensional information on the existing conditions. “You’ve got information on the colors, you’ve got very precise measurements,” he says. "The scans are accurate enough to pick up the slight deviations in the structure, important from an engineering standpoint to understanding what the loads are doing through the structure.”

Tallon once said the scans offered accuracy to within five millimeters.

Russo says that while 3D scanning does require a trained individual to get useful information, “what academics are doing can absolutely be valuable to engineers and contractors.”

While the scans provide much precision, they won’t answer every question when it comes to an ambitious five-year rebuild of Notre Dame. Already the discussion has started on whether the building should be recreated as it was or if it should have a different spire. Also, with so many imperfections within the construction, Russo wonders how close officials wish to adhere to original construction methods. Will officials allow more modern construction techniques to counter imperfections? “There are probably very passionate debates on how that would get done,” Russo says.

“Which Notre Dame are we going to rebuild?” Davis asks. “It is a kind of beautiful Frankenstein of all these different parts, 12th, 13th, 14th and 19th Century parts, so is that the one we are going to restore or is this an opportunity to undo some of the restorations of the 19th Century where we think they got it wrong and rectify errors we have identified? It is a ticklish and complex decision.”

Davis pointed to an example of a rebuild of York Cathedral in England following a 1984 fire where officials had the building reconstructed to previous aesthetics, but with the addition of a fire-suppression system.

John Ochsendorf, MIT professor in the departments of architecture and civic and environmental engineering and current director of the American Academy in Rome, notes that material choices alone provide uncertainty in the process. While saying the scans done by Tallon, someone he worked with, gives intricate information on the stones and timber used in construction, that leads to more questions.

“[The scans] could potentially be very useful for restoring the historical timber roof, but knowing the geometry is only one aspect,” Ochsendorf says. “It is not easy to procure oak timbers of the size needed. Centuries ago, large oak elements were harvested by royal carpenters from the king’s forests, were they could grow for centuries. Today it is very difficult to find solid oak timbers of the dimensions that would be needed. These elements could be 2 ft by 2 ft in cross sections and could be 20 to 30 ft in length.”

Russo says that the scans capture only the surface of the objects and engineers may need to go to historic record drawings that describe in more detail the full assembly method.

Whether from catastrophic events, such as in Paris or York, or for renovation efforts, such as one Russo’s team worked on at Union Station in Washington, D.C., where the laser scanning offered a key part of documentation to ensure historic preservation, laser scans have become a critical way to help document — and potentially save — history.

“It is going to help those who are going to restore a damaged structure in it is going to cut their timeline down, help them restore it more accurately,” Russo says. “In many cases a lot of these historic sites have no documentation. When that happens, I don’t even know how you would go back to reconstruct it and it would be lost forever.”

Post a comment to this article

Report Abusive Comment