LUMBER BRIDGE, N.C. — The 75,391-sq.ft. Sandy Grove Middle School is the nation’s first net positive leased school — meaning that it returns more energy to the grid than it consumes.

Tracking LEED Platinum Certification using the LEED 2009 for Schools Model, the Hoke County school system expects the project to save the county $35 million over the next 40 years, including $16 million in energy costs alone, and it is the first government building whose construction was financed entirely from its own energy savings.

The school employs a number of sustainable measures, including solar panels; high-efficiency plumbing fixtures; storm water management; spray-foam insulation in the building’s structure, which creates an uninterrupted air barrier; and innovative geothermal systems for heating, cooling and hot water.

Geothermal report card

The geothermal system uses the naturally renewable ground temperature as a heating and cooling source and is a major contributor to the school’s substantial energy savings. The geothermal system was a contributing factor to this because it uses the earth’s naturally renewable ground temperatures, which results in energy payback, reduced energy costs and an overall discounted energy bill overtime.

According to Steven Daley, P.E., managing principal of Optima Engineering, “The school is likely saving $8,000 to $10,000 from the geothermal system itself. Without this system the building couldn’t achieve the highly energy-efficient status it has today.”

Sandy Grove utilizes a closed-loop geothermal system that comprises 160 bores, 300 feet deep. A closed loop system consists of underground continuous piping loops filled with fluid that transfers the ground temperature to the geothermal heat pump. Engineers installed Sandy Grove’s loop vertically — which requires less space — below the school parking lot on the east side of the school. Geothermal loops may be installed under a sports field, parking lot or similar open, flat surface spaces with satisfactory soil characteristics.

Two-stage Bosch Thermotechnology AP models — currently sold as the LM model — and larger single-stage FHP commercial EP models comprise the 49 geothermal heat pumps in Sandy Grove’s HVAC system. A separate geothermal water-to-water heat pump provides domestic hot water, further reducing energy requirements for the school.

“In this particular project, air-source heat pumps would not have achieved the level of energy efficiency required. A geothermal heat pump reaches high efficiencies —300% to 600% — on design days, compared with 175% to 250% for air-source heat pumps. In addition to being highly energy efficient, water-source heat pumps are also cost effective over time. The installation may be greater upfront, but at the end of the year the owner or customer will see a pay back in a reduced energy cost. The energy cost is discounted year-over-year for putting in the system,” said Arthur Kunz, Bosch commercial sales manager for the Southeast.

These geothermal heat pumps help to reduce overall operating costs as well as carbon dioxide emissions, making them an important factor in the school’s overall sustainability. In total, the 49 pumps provide 209 total tons of cooling load across three wings of eight classrooms each, a 450-seat gymnasium, media center and 258-seat kitchen/dining areas. Each classroom contains its own dedicated heat pump and thermostat, therefore allowing for individual environments to be maintained.

Because the temperature of the ground is relatively consistent, the system delivers a constant flow of 55°F water to the pumps, which means they require less energy to regulate Sandy Grove’s indoor temperature. An outside dedicated air system works to bring in ventilation air, so once the thermostat set point in a particular space is reached, the heat pump cycles off and delivers neutral air to the classroom.

The building automation system monitors and controls all HVAC systems. The system also is tied into carbon dioxide demand control sensors in the gym and cafeteria, so the outside air dampers can modulate based upon occupancy levels.

One of the challenges faced on this project was with the school’s specific controls and building management system. “Fortunately, the Bosch FHP commercial EP models are open to all different control schemes. This is unique to Bosch because our solutions are flexible with other control systems, which allows us to mount and wire other manufacturers’ products. For this specific project, we interfaced with Siemens controls,” said Kunz.

Practicing what it preaches

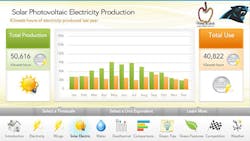

Sandy Grove is leading by example, giving its students a “hands-on” approach to sustainability. Students, teachers and the general public can view real-time geothermal system operations on the school’s building dashboard, including the current in and out temperature levels of the ground pumps, and daily kBTU profiles for geothermal heating and cooling. The dashboard itself contributed to the school’s pending LEED certification with an Innovation and Design LEED credit, as teachers wrote more than 20 hours of instruction for each grade level based around the dashboard.

“It is very exciting to see a water-source heat pump project in a K-12 school take the next evolutionary step,” said Keith Chapman, Raleigh, N.C., office manager for Thermal Resource Sales, the FHP sales representative on the project, which worked closely with the installing contractor, Bass Air Conditioning, and engineer of record, Optima Engineering.

“We have been involved in hundreds of K-12 school projects, but this represented the first true net zero or net-positive installation. It was a productive experience working with a forward-thinking engineer, Steve Daley of Optima Engineering, and a professional and thorough mechanical contractor, Alan Bass of Bass AC.”