PREPRUFE® Plus is put to the test, proving long-term performance

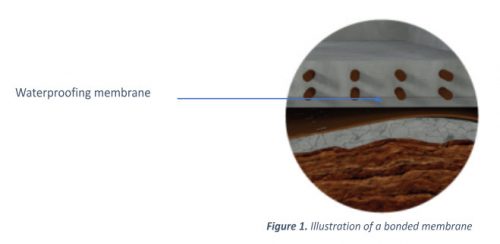

It is critical that waterproofing membranes perform not only during construction but throughout the life of the structure, resisting lateral water migration even in instances where the membrane could be punctured.

Current standard testing of hydrostatic pressure resistance of a waterproofing membrane is based on ASTM D 5385 which tests a fresh specimen, with no water immersion or aging, at water pressure up to 689 kPa (100 psi). However, below grade waterproofing needs to maintain an intimate bond to concrete and prevent lateral water migration after constant exposure to water, a result of groundwater in the soil, throughout the life of the structure. Standard bond to concrete and hydrostatic tests may not represent the real-life situation a waterproofing membrane must withstand to be effective.

Several decades ago, GCP Applied Technologies (GCP) modified the ASTM D 5385 test method to test the hydrostatic pressure resistance performance of a pre-applied waterproofing membrane with a breach in the membrane. This test method has become an industry standard and is called the ‘lateral water migration resistance test’.

Lateral water migration resistance

Lateral water migration resistance (LWMR) is the ability of a pre-applied waterproofing membrane system to prevent/restrict the passage of water between the waterproofing membrane and structural concrete in the event of a breach. For this to be achieved, the membrane must be intimately and continuously bonded to the structural concrete slab.

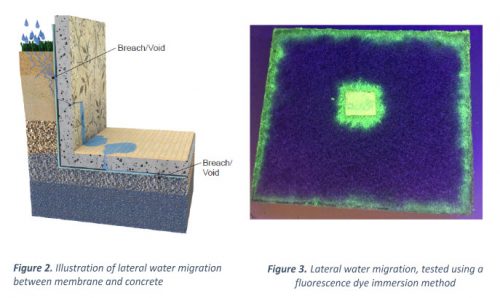

If a waterproofing membrane without this performance characteristic is punctured or improperly installed, water which bypasses the membrane would not be confined to the breached location. Under hydrostatic pressure, this water can migrate between the waterproofing membrane and the structure (Figure 2 & 3). Once water has entered the structure, migration around and within concrete can result in significant leaks, and the source can be difficult to find. Repair and remediation of such circumstances is expensive, often requiring continuous grouting and/or costly alternatives. The LWMR of a waterproofing membrane can be correlated directly to the technology used to provide bond to concrete performance. All bonded membranes are not equal in this respect and a closer examination of the bond mechanism is needed.

The LWMR of a waterproofing membrane can be correlated directly to the technology used to provide bond to concrete performance. All bonded membranes are not equal in this respect and a closer examination of the bond mechanism is needed.

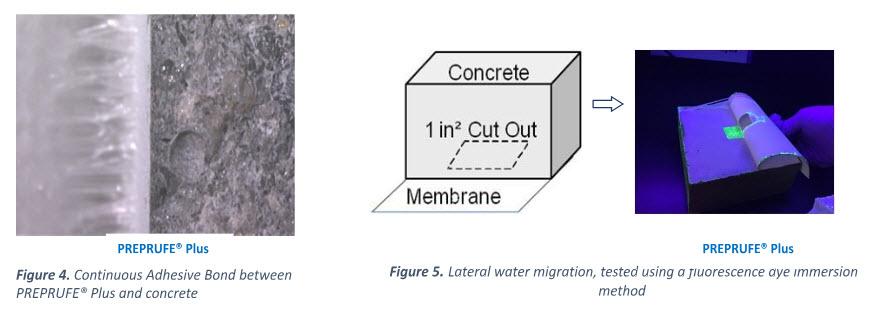

The PREPRUFE membrane adhesive interacts with the proprietary protective coating to form an intimate adhesive bond with the concrete cast against the membrane. (see Figure 4 & 5). If a breach occurs in the membrane, the adhesive prevents water under hydrostatic pressure from migrating between the membrane and the concrete, limiting the risk of waterproofing failure. This bond is continuous and was developed to provide lasting performance. Independent testing shows the PREPRUFE waterproofing membrane can resist lateral water migration at 231 feet of hydrostatic pressure even after long term immersion in water.

PREPRUFE LWMR testing

Given the design life of most modern structures, it is vital that the bond to concrete technology can withstand subgrade conditions throughout an extended period. During 2003 to 2006, The French Tunneling and Underground Space Association (AFTES)—known in French as L’Association Français des Tunnels et de l’Espace Souterrain—a globally recognized independent testing body, carried out a lateral water migration test based on modified ASTM D 5385 of the PREPRUFE 300R membrane immersed under water for a period of three years at a test pressure of 700 kPa (102 psi or 231 ft of hydrostatic head pressure) to verify its LWMR properties. At the end of the three-year test period, AFTES certified that no leaks or tearing of the PREPRUFE 300R membrane were observed on the 21 samples tested after continuous exposure to water.

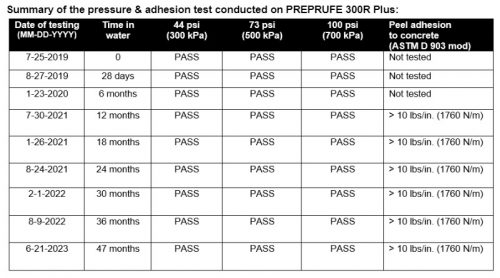

From 2019-2022, after the addition of the ZipLap™ and removing the release liner, enhancing ease and speed of installation, the same AFTES test was repeated on PREPRUFE 300R Plus waterproofing membrane. Testing was prepared and conducted under the supervision of a representative from KIWA BDA testing lab from Gorinchem (Netherlands). KIWA BDA is a globally recognized testing, inspection, and certification institute of the building envelope. Representatives of KIWA BDA were present during sample preparation and scheduled periodical water pressure tests.

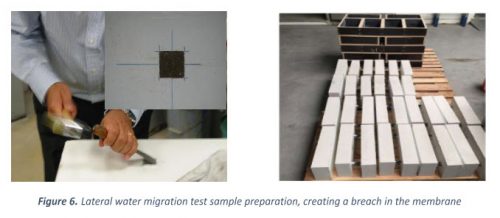

PREPRUFE 300R Plus test samples were created by casting the concrete over the membrane and creating a breach in the membrane representing a puncture that could occur in real site condition (Figure 6). These samples were immersed in water in a container and stored safely. The water level was maintained and controlled.

Three PREPRUFE Plus samples were tested at the end of each 1, 6, 12, 18, 24, 30 and 36 months, as per AFTES modified ASTM D 5385. No water leaks were observed. Each PREPRUFE Plus sample remained bonded around the breach. Lateral water migration was not able to occur due to the PREPRUFE bond to concrete technology.

Additionally, each water immersed sample was tested for peel adhesion to concrete as per ASTM D903. PREPRUFE Plus adhesion to concrete was found to be consistently more than its published value throughout the test duration, attesting to Preprufe Plus’s long-term adhesion.

After successful testing of PREPRUFE 300R Plus, at the end of the third year, KIWA BDA issued the Final Witness Report ref: 0140-L-19/3 REV 01.

PREPRUFE adhesion testing

In addition to LWMR evaluation, GCP has conducted several adhesion studies on PREPRUFE under different environmental conditions, such as BTEX solution and high pH environment sample immersion, which shows no significant change in the bond strength. The environmental conditions used in this study to evaluate long term impact on performance represent the worst-case scenarios and are highly unlikely to occur. In practice, the concrete substrate will not contact groundwater unless the PREPRUFE membrane was mechanically damaged and perforated before the concrete was cast. However, these immersion test results show that even under a worst-case scenario, the membrane continues to adhere strongly to concrete. The LWMR studies reinforce results from the adhesion studies to support the waterproofing integrity of the bonded system.

Summary

The standard ASTM D 5385 test is conducted for a maximum of seven hours and on a fresh sample. PREPRUFE Plus has been tested in more stringent, real-life conditions.

Both LWMR and adhesion data indicate that PREPRUFE membranes will continue to exceed GCP published performance data and provide an effective barrier to water ingress and water migration over extended periods of time, as required for the stability of the built foundation.

All information listed in this section was submitted by GCP Applied Technologies.

Kenilworth Media Inc. cannot assume responsibility for errors of relevance,

fact or omission. The publisher does not endorse any products featured in this article.

I don’t believe this test method is an industry standard. Please advise or clarify.

Thank you

It’s not a standard test method yet. Standard Lateral Water Migration Testing as per ASTM D 5385 mod is under ASTM review, please see this link: https://www.astm.org/workitem-wk83821. This article talks about how GCP’s PREPRUFE testing is taking the lead on this standard, and in even harsher conditions like testing of lateral water migration after long-term water immersion, to set a new performance benchmark in blindside waterproofing.

Thank you for the reply. I am aware of the ASTM Work Item as I am involved with the committee. I did just want to clarify for the reader of this article the statement that was made; “This test method has become an industry standard and is called the ‘lateral water migration resistance test’”.

The introduction of a new industry standard for waterproofing testing is a crucial step towards ensuring building durability and safety. This initiative establishes a standard of excellence and promotes trust and reliability within the construction sector. I would like to express my thanks to the team responsible for this standard for their dedication to quality and innovation!

“This article discusses a new waterproofing testing methodology in the construction field that ensures reliability and safety in building projects, representing a significant advancement in durability.”