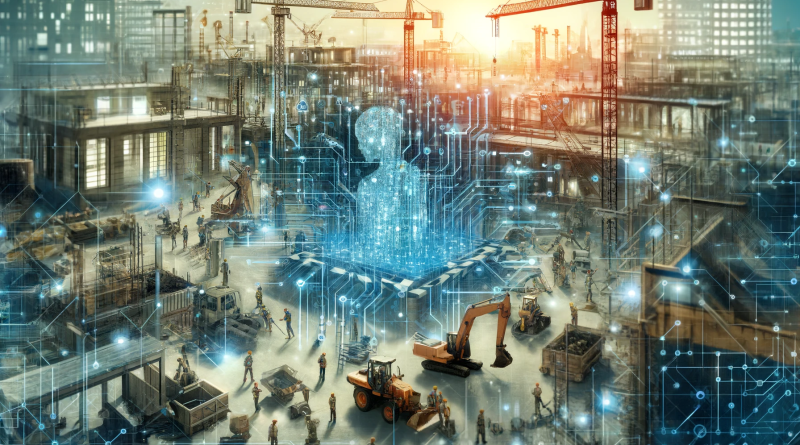

AI is Coming, Are You Ready?

The construction industry is embracing a digital revolution, with artificial intelligence (AI) emerging as a transformative force. Historically, construction has relied on manual labor and traditional project management techniques, but the advent of AI offers a new approach that optimizes efficiency and enhances safety. AI technologies, such as machine learning algorithms and computer vision, are streamlining processes across the construction lifecycle.

Companies that recognize the importance of AI are leading the way in revolutionizing construction operations. For instance, Japan’s Komatsu has developed a “Smart Construction” initiative that integrates AI to monitor job sites, improving productivity by predicting potential delays and equipment malfunctions. Similarly, Skanska is leveraging AI to analyze historical project data, identifying patterns that help mitigate risks and enhance project delivery.

Key trends driving AI adoption in construction include the need for greater efficiency in project management, reducing cost overruns, and meeting tight project timelines. The technology also aids in analyzing massive data sets, offering insights that were previously inaccessible with traditional tools. With increased digital integration, AI systems can now leverage data from building information modeling (BIM) software, drones, and IoT sensors to provide real-time insights, enabling data-driven decision-making in project management.

The industry’s digital transformation is supported by governments and private sectors globally, as they recognize the potential of AI to significantly impact productivity. McKinsey & Company projects that global construction productivity could increase by as much as 50% by adopting digital tools, including AI. The widespread adoption of AI signifies the dawn of a new era in construction, where traditional practices are enhanced by cutting-edge technology to deliver superior outcomes.

Harnessing Predictive Analytics for Construction Insights

Predictive analytics is reshaping the construction industry by offering unprecedented insights that enhance project planning and execution. This AI application analyzes historical data to identify patterns, helping project managers anticipate and mitigate risks before they become costly problems. Its adoption in construction is growing due to the rising complexity of projects and the need to maintain tighter control over timelines and budgets.

One of the primary benefits of predictive analytics in construction is improved project scheduling. By analyzing past project data, AI systems can accurately predict potential delays due to factors like weather, supply chain disruptions, or workforce shortages. For instance, Procore, a construction management software company, uses predictive analytics to monitor projects in real-time, providing insights that allow managers to adjust schedules and resources proactively.

Predictive maintenance is another key advantage. AI systems analyze data from sensors embedded in machinery to predict equipment failures before they occur. This reduces unexpected downtime and extends the lifespan of construction equipment. Caterpillar, a leading heavy equipment manufacturer, offers a service called Cat Connect that uses predictive analytics to monitor machine health, enabling customers to minimize equipment downtime and improve productivity.

Predictive analytics also enhances cost estimation. By comparing historical project costs with real-time data, AI helps companies refine their budgeting and reduce cost overruns. This is crucial in an industry where profit margins are often razor-thin. Dodge Data & Analytics found that firms using predictive analytics for estimating costs were 23% more likely to stay within budget.

The value of predictive analytics lies in its ability to transform vast amounts of data into actionable insights. As construction companies adopt AI-driven tools, they gain a competitive edge by proactively addressing challenges and optimizing their operations. With predictive analytics, the construction industry can anticipate problems before they arise, ensuring projects stay on schedule and within budget.

Automated Robotics: A New Workforce in Construction

Automated robotics are redefining the construction workforce by introducing unprecedented levels of efficiency, precision, and safety. While traditional construction relies heavily on manual labor, robots are increasingly taking on repetitive and dangerous tasks, allowing human workers to focus on complex, strategic activities. The use of robotics in construction ranges from automated bricklaying to precision concrete pouring.

The construction industry has long struggled with labor shortages and safety concerns, making robotics an attractive solution. Bricklaying robots, like the semi-automated mason (SAM) developed by Construction Robotics, can lay up to 3,000 bricks a day, significantly more than a human worker. This improves productivity and ensures consistent quality, reducing the need for costly rework.

Similarly, construction robots like rebar-tying machines automate repetitive tasks that are physically demanding and injury-prone. TyBOT, an autonomous rebar-tying robot, has been deployed on bridge and road construction sites to accelerate rebar tying and alleviate the strain on human workers. Such machines not only speed up the process but also ensure accuracy and reduce injury risks.

Robots are also used for 3D printing in construction. Companies like Apis Cor have developed mobile 3D printers capable of constructing small homes in just 24 hours. These printers offer high levels of precision and allow for innovative design solutions that were previously not possible with traditional construction methods. This technology holds great promise for quickly and affordably addressing the global housing crisis.

Site inspection is another area where robotics excel. Drones equipped with AI capabilities can survey large construction sites, capturing data that can be analyzed to assess progress, identify safety issues, and improve project planning. These aerial inspections are faster and more accurate than manual methods, reducing the need for human inspectors to navigate hazardous conditions.

Robotic automation represents the future of construction, where human-robot collaboration can lead to safer, more efficient worksites. As the technology continues to evolve, it will become an integral part of construction projects, enhancing productivity and reducing costs.

The Future of AI in Construction

As the construction industry embraces AI, navigating this transformation requires strategic planning, investment, and a willingness to evolve. Companies that aim to remain competitive must adapt to the changing landscape by upskilling their workforce, managing technology adoption costs, and addressing the ethical and security challenges of data usage.

Workforce upskilling is crucial, as construction workers need to acquire new skills to interact with AI tools effectively. Organizations should invest in training programs that teach employees how to leverage AI for tasks like predictive maintenance, data analysis, and robotic supervision. For example, leading firms are partnering with educational institutions to develop specialized training programs that bridge the skills gap in the workforce.

Cost management is another significant challenge, as implementing AI technologies requires substantial initial investment. However, the return on investment (ROI) can be significant, with improved efficiency and reduced costs making AI adoption a worthwhile endeavor. Companies can explore pilot projects to test the technology before large-scale implementation, ensuring they can assess the potential benefits and adjust strategies as needed.

Data security and ethics also pose challenges in AI adoption. As construction firms collect vast amounts of data, they must ensure it is stored and managed securely to prevent breaches. Additionally, ethical considerations around data privacy and worker surveillance need to be addressed, with clear guidelines and transparency in how data is used.

The future of AI in construction looks promising, with emerging technologies poised to transform the industry further. McKinsey projects that by 2030, AI-driven digital solutions could reduce project costs by 20% and enhance productivity by 50%. This potential has encouraged governments and industry leaders to push for wider AI adoption, investing in research and development to drive innovation.

In the coming decade, we can expect to see AI further integrated into construction processes, with innovations like digital twins enabling real-time project monitoring and augmented reality enhancing design visualization. Companies that embrace these changes will be better positioned to navigate the challenges of the future, leading the industry into a new era of digital transformation.

Sources: