By John A. Jackson, AIA

Photo courtesy Simpson, Gumpertz & Heger; Illustration (right) courtesy Enclos

It is early morning on a summer day in the mid-Atlantic. The temperature dropped overnight, and the sun is just beginning to rise, lighting the glass façades of the skyline, as the humidity and heat start to build up. When walking down the busy sidewalks during the morning commute, one might notice something odd when looking up at some of the glass skyscrapers. The spandrel glass at the floor levels appears hazy and fogged over compared to the clear windows below. It is unclear, but it looks like moisture may be trapped on the inside of the glass at the spandrels.

It is early morning on a summer day in the mid-Atlantic. The temperature dropped overnight, and the sun is just beginning to rise, lighting the glass façades of the skyline, as the humidity and heat start to build up. When walking down the busy sidewalks during the morning commute, one might notice something odd when looking up at some of the glass skyscrapers. The spandrel glass at the floor levels appears hazy and fogged over compared to the clear windows below. It is unclear, but it looks like moisture may be trapped on the inside of the glass at the spandrels.

When walking by a few hours later during a coffee break, one notices the spandrel and vision glass now look the same—the haziness and fog have disappeared. As a result, it is fair to say one may think there was a problem with the glass earlier, but what is really going on?

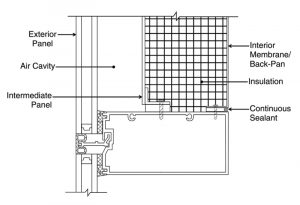

Glass spandrels are a common design strategy used to opacify floor levels in building façades. These opaque glass assemblies are integrated into glazing systems, such as glass curtain walls or window walls, to provide visual continuity with adjacent vision glass to render an all-glass look to the building façade. Certain glass spandrel designs, such as shadow boxes, can also provide a greater expression of visual depth in comparison to back-painted spandrel glass or glazed-in metal panels. Spandrel assemblies typically include an exterior panel (sometimes they include an intermediate panel) and are often backed by insulation, either foil-faced or with a metal back-pan.

Although simple in concept, the physics and technical design considerations of glass spandrels and shadow boxes can be quite complex and must be carefully considered. These include the potential for heat build-up in the cavity, glass differential thermal stress, risks of cavity condensation, thermal performance, air-water-vapor seal, edge-of-slab fire safing, and accumulation of dust/debris in the cavity. Project-specific exterior climate and interior psychometric (i.e. temperature and relative humidity) conditions must also be considered. In addition, glass spandrel design must consider the method of construction of the glazing system, whether factory-glazed (e.g. unitized curtain wall or window wall) or field-glazed (e.g. stick-built curtain wall). Temporary protection during storage, transportation, and installation, as well as in-service considerations such as glass replacement must also be factored into the equation.

Illustration courtesy Simpson, Gumpertz & Heger

Like many issues with glazing systems, design considerations for glass spandrels must be balanced carefully against the project-specific performance requirements, including considerations for construction, schedule, cost, and maintenance in-service. A summary of these important design considerations will be provided, along with recommendations through lessons learned from the author’s experience on projects using glass spandrels and shadow boxes within the building façade.

Definition of spandrels

The Fenestration and Glazing Industry Alliance (FGIA) and American Architectural Manufacturers Association (AAMA) defines spandrels as “the opaque areas of a building envelope which typically occur at floor slabs, columns, and immediately below roof areas.” Like a glass panel, spandrel assemblies are often ‘glazed into’ the framing (e.g. aluminum mullions) of glazing systems. Spandrels typically incorporate some combinations of the following components, listed from exterior to interior (Figure 1).