By Mark D. Hagel, PhD., P.Eng, Mike Lafontaine, CTR., SSG., SD

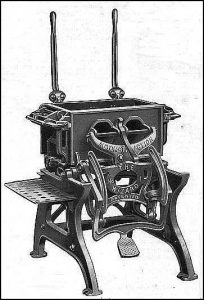

Hollow concrete block masonry was first used as a building material around 1870, when wooden molds were developed to produce concrete block units from a relatively dry mixture of sand, cement, and water. Around 1900, the first cast iron block producing machine (Figure 1) was patented and a decade later, there were more than 1,000 producers of concrete block in North America.

In current construction, concrete masonry units (CMUs) are used as both structural and architectural building materials. CMUs are ideal candidates for carbon dioxide (CO2) sequestration because they are porous and carbonate quickly when left exposed to the atmosphere (weathering carbonation) and can also be cured with CO2 in a closed chamber with either low-pressure or high-pressure steam (pre-carbonation). For CMUs, CO2 absorption by mass of cement binder is roughly 6.3 percent. This translates to approximately 0.250 kg (0.5 lb) of CO2 sequestered per standard 198 mm (7.8 in.) hollow CMU. The carbonation of concrete masonry is not only environmentally friendly, but it can also achieve higher early strength.

Concrete block masonry and architectural block masonry also support resilient buildings. The more extreme weather events being experienced throughout the world can be mitigated with concrete masonry as it is fireproof, highly impact-resistant, and can store moisture without degradation. A fireproof material provides resiliency against forest fires, while the high impact- resistance protects against hail damage and impact damage during high wind events such as tornadoes.

Concrete masonry’s ability to store water provides resiliency against floods and can also reduce water loads on stormwater systems when used as veneers. Concrete masonry can absorb more water during heavy rain events than siding or glazing, which shed water to the ground and storm drains. They can absorb water without degradation to the cladding. Although there is no lab testing for resiliency against floods, there are decades of proven performance where concrete block does not mold, rust, or rot. The location of the rebar, when fully grouted, provides adequate protection for a single wythe masonry wall, 95 mm (3.7 in.) of concrete cover for rebar, and is typically protected by an air vapor barrier that is highly resistant even to standing water.