By David Peragallo

Tensile architecture, also known as tensile structures or fabric architecture, is becoming a popular choice for applications such as stadiums, airport hubs, train and bus stations, exhibition halls, event pavilions, and temporary structures such as festival tents. This structural design approach uses tension forces to create stable and visually striking structures.

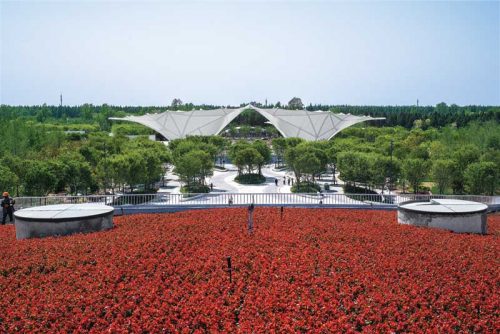

Tensile architecture stands at the forefront of contemporary design, offering architects and designers a realm of possibilities that merge functionality with aesthetic innovation.

Design considerations

Successful tensile architecture demands a holistic approach that considers aesthetics, functionality, environmental factors, and structural integrity. Tensile structures often create unique spatial experiences, whether in public spaces, commercial buildings, or recreational areas. This is why collaboration between architects, structural engineers, and other specialists is essential, to navigate its technical intricacies and bring forth innovative and enduring tensile structures.

One of the key benefits of tensile architecture is its ability to integrate form and function. This means when striking a balance between aesthetics and functionality, designers must consider how their work will influence the experience of the users or occupants.

Though boasting remarkable environmental adaptability, climate analysis is vital for a successful tensile design. Understanding the local climate is crucial for resiliency, as wind and snow loads, temperature variations, and exposure to sunlight impact the structure’s performance. Computational tools and simulations can be used to help predict environmental effects.

Another important consideration is identifying opportunities to integrate sustainable features. Tensile structures can facilitate natural ventilation, daylighting, and rainwater harvesting. Further, optimal orientation and the use of eco-friendly materials used to build tensile structures contribute to sustainability.

From a structural engineering standpoint, load distribution and integration of compression elements should be carefully considered. Tensioned elements must distribute loads effectively to ensure structural stability. The design should account for factors such as wind, snow, and dead loads. Collaborating with structural engineers is essential to ensure the structure can withstand these loads. Further, incorporating compression elements, such as masts or columns, provides additional support. The combination of tension and compression elements enhances the overall structural integrity.

When it comes to the choice of material, current advancements allow for a wide variety of membranes, cables, and connections. Specifiers should choose membrane materials based on their mechanical properties, durability, and aesthetic characteristics. Polytetrafluoroethylene (PTFE), polyvinyl chloride (PVC), ethylene tetrafluoroethylene (ETFE), structural, transparent, fluorinated envelope (STFE), and other high-strength fabrics offer different advantages. They should also consider factors such as translucency, color options, and resistance to environmental degradation. High-strength cables, usually made of materials such as steel, are critical components. Understanding the tensile strength, elasticity, and corrosion resistance of these materials is vital in selecting the appropriate type and diameter. To meet durability requirements, select materials that withstand environmental conditions over time. UV resistance, corrosion resistance, and resistance to wear and tear are crucial for ensuring the longevity of the tensile structure.