The majority (60-80%) of CMMS implementations fail for the same reason that the majority of ERP systems and IWMS systems fail… the lack of due consideration of robust, lead, processes and procedures. Quite simply, technology is used to automate existing processes vs. implement more efficient, transparent, collaborative, and accurate policies and procedures.

For example, virtually none of the major (or even minor) CMMS or IWMS technology vendors incorporate a standardized cost database, such as RSMeans, from which users could compare their actual material, equipment, and labor costs against a localized reference standard. “Just plain stupid”, right?

What good is a CMMS system into which an Owner inputs their own experiences without comparison to industry averages, best-practices, or any third party metrics? What can these Owners possible be benchmarking against? How can goals, objectives, targets be established?

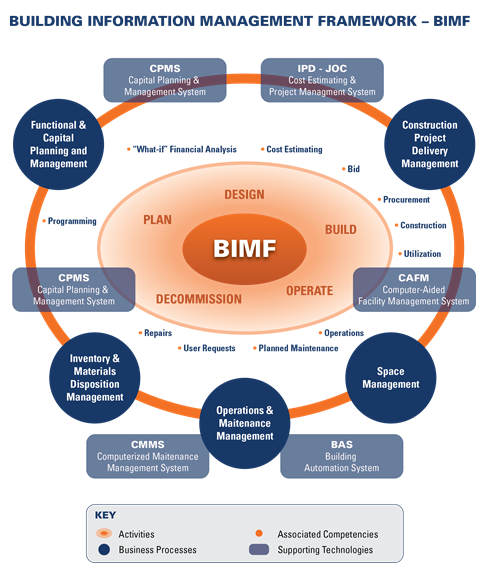

1. How many Owners understand the difference between CMMS (Computerized Maintenance Management Systems) and CPMS (Capital Planning and Management Systems) and the absolute requirement for BOTH relative to efficiently managing larger facility portfolios?

2. How many Owners continue to be reactive in their capital allocation, even with a CMMS…aka spending 60%+ of their budgets on emergency or unplanned maintenance vs. planned, preventive and/or predictive maintenance?

3. How many Owners still wallow in design-bid-build and change-orders, legal disputes, and poor quality vs. collaborative efficient methods such as Job Order Contracting and Integrated Project Delivery?

4. …..

The sad part is, there is a lot of information out there on efficient life-cycle management of the built environment supported by digital technology. Why are many facility management executives still supporting unsustainable business practices? That’s the hard question.

There is so much employee changeover nowdays that at some point the CMMS systems generally go without someone to operate them. I have programmed a few software packages from intial startup to full functional operation and have since left the company. Only one CMMS system that I setup and aware of is still being maintained. Most companies are advertising jobs with descriptions that include the ability to start up a CMMS work order system, yet when the key person leaves the organization the CMMS is the first system to get swept under the rug along with the preventive maintenance program!

You hit that one on the head