Job order contracting (JOC) is a way for organizations to get numerous, commonly encountered construction projects done quickly and easily through multi-year contracts. JOC reduces unnecessary levels of engineering, design, and contract procurement time along with construction project procurement costs by awarding long-term contracts for a wide variety of renovation, repair and construction projects.

With an emphasis on partnering and team work between owners and contractors, JOC provides the methodology to execute a wide variety of indefinite delivery, indefinite quantity, fixed-price, multiple and simultaneous orders for renovation, rehabilitation and repair work for facilities and infrastructures.

Best Value = Best Return on Investment

JOC contractors are selected on qualifications and performance at a best value, lowest responsive and responsible bidder, or a combination of both depending on local, state or federal statutes. JOC is about performance, reliability, dependability and quality. At the same time, JOC is about results and working within budget and time constraints. The JOC contractor provides “on call” construction services from concept to close-out.

Job Order Contracting is a proven construction delivery method that delivers more projects on-time and on-budget than traditional methods.

JOC today has more than a 25-year record of implementation across multiple market sectors. While having its roots in United States Department of Defense; non-DoD Federal Government, State/County/Local Government, Education, Healthcare, Transportation, and Utilities are now included as JOC users and proponents. Not only public sector but also private sector facility owners are expanding the use and implementation of the JOC construction delivery method.

Currently, there are hundreds of successful contracts going by the JOC name or by its counterparts of delivery order contracting (DOC), task order contracting (TOC) and simplified acquisition of base engineering requirements (SABER).

A designated non-profit organization dedicated to education and best practices was formed in 1995 to serve as a resource for information. Further research can be found at Center for Job Order Contracting Excellence.

Basic principles of Job Order Contracting

A major element of the JOC contracting process is the use of a unit price book (UPB), which provides preset unit line item costs for specific construction tasks. The unit price book can cover the major of construction, repair or maintenance tasks, whether it’s replacing air filters, installing carpeting, replacing windows or doors, or even painting or it can be limited to specific areas of work or a particular trade. If a task is not in the UPB, it can be negotiated, priced and added at any time to the book. The latter is typically referred to as a non-prepriced (NPP) line item. For many JOC contracts a limit is placed upon the percentage of NPP costs allowed per task order, generally this is 10%.

Contractors can be selected based on best-value or low bid, depending upon the owner’s requirements. Best value, however, is the hallmark of LEAN and collaborative construction delivery methods, and the most appropriate for “true” JOC. As part of its proposal, or bid, the contractor submits a coefficient (a multiplier) to be applied to the preset unit prices appearing in the UPB. The coefficient must include not only the contractor’s overhead and profit, but also any adjustment that may be needed to the UPB prices based on the contractor’s costs in the local area of the contract(which are functions of labor costs, subcontractor base, market conditions and client-specific conditions).

After contract award, and during the course of the contract, the coefficient will be used to calculate the price for each project which will be the preset unit prices multiplied by the quantity multiplied by the coefficient.

JOC is performance-based contract. JOC contracts don’t define actual, individual jobs but normally award a potential maximum amount of work over a year. For example, a contract may have an annual maximum of $5 million or more but only a minimum guaranteed amount such as $35,000. As a result, the JOC contractor is not guaranteed any level of revenue, driving the constractor to generate the best performance possible.

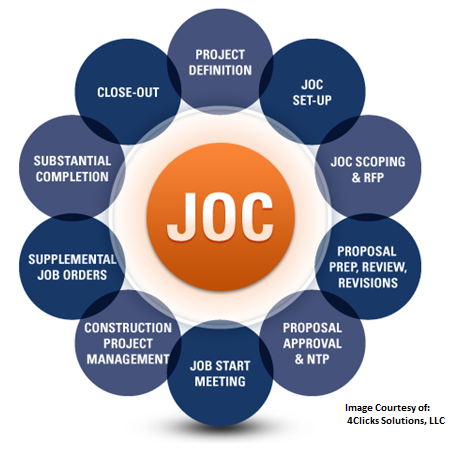

For each project, the owner and the contractor follow the same five steps: (1) Conduct a joint scope meeting at the site to review and discuss the work and the construction schedule; (2) prepare a detailed scope of work; (3) contractor prepares a price proposal using unit prices from the UPB, quantities, and coefficient, and submits a proposed construction schedule, list of subcontractors and other documents required by owner; (4) owner reviews price proposal to make sure the right tasks and quantities were used; (5) if owner is 100% satisfied with price, schedule, subcontractors, etc. owner may issue work order for the project, (6) Owner negotiates certain components of line items of the project as required, (7) a notice to proceed (NTP) is award post successful Owner/Contractor negotiations.

Sample JOC Process: Figure Below

This relationship carries with it a strong motivation for the JOC contractor to provide outstanding service and quality work to receive additional work orders, because the amount of work being assigned by the facility owner or manager is based on the JOC contractor’s performance. The agreement should also foster increased communication between the contractor and owner to enhance the partnership aspect of the JOC contract.

Key elements

A JOC contract follows certain procedures leading to an agreement focusing on achieving good work performance and reasonable costs. Among the procedures leading to the formalization of a JOC contract are the following items and provisions:

- Standard specifications established in a master contract with a summary of work, also including any specific or client-driven conditions.

- A unit price book containing preset unit prices for construction tasks. The unit prices may also include a localization factor.

- Facility owner issues a request for qualifications (RFQ), evaluating firms using best-value, performance-based criteria, or an invitation to bid awarding to the lowest responsive and responsible bidder.

- A guarantee of minimum amount of work for the contractor. This is usually a small amount for consideration – a requirement in most states for contracts.

- Issuance of contractor’s work orders based on owner’s requirements.

- Costs for individual work orders are calculated by multiplying the preset unit prices by the quantities multiplied by the contractor’s coefficient.

- Open communication between facilities team and JOC contracting team, including a kick-off partnering session between everyone utilizing the contract.

Advantages

The major advantages of job order contracting include:

- Fast and timely delivery of projects.

- Low overhead cost of construction procurement and delivery.

- Development of a long term Owner/Contractor “partner relationship” based on work performance.

- Reduced legal fees, and virtual elimination of change orders.

- Transparency with itemized unit pricing.

- Elimination of change orders.

- Standard pricing and specification utilizing a published unit price book (UPB), resulting in efficient and effective estimating, design, and fixed-price construction.

- Lower overall total cost

Top-performing JOC contractors achieve a high percentage rate for completion of projects on time and on budget. Also, the JOC process provides for a single contract to be used for the delivery of multiple or repeated work orders without having to re-bid the same work as required in other commonly used delivery systems. It allows for back and forth communication and development efforts throughout a project. This differs greatly from the one way efforts of design–bid–build. JOC provides the greatest advantage in situations involving recurring work when delivery times, type of work and quantity of work are indefinite. While JOC is not used for major new construction, it is best for minor construction, adjustments, renovation, repair and maintenance of facilities.

Other advantages include:

- Partnering and performance incentives result in high-quality construction and service and enhanced quality control. Quality JOC contractors have reduced and even eliminated punch lists.

- Simplified design documents and acquisition processes negate the need for complicated and repetitive contract documents and reduce contract administrative costs.

- The speed of JOC contracting ranges from 10 days to 21 days from request to construction start, since JOC projects don’t demand soliciting and acquiring a contract along with detailed plans and specifications.

- Facility owners do not have to provide a complete design, but rather rely on the JOC contractor to produce any essential drawings for the design.

- Employment of smaller subcontractors in the area to perform the work, allowing for the majority of the project funds to be spent locally.

- Minimal risk for the owner in the event of problems with the contractor because the owner can stop using the contract at any time. If a performance-based system is also used, the JOC contractor can be terminated for lack of performance.

- A win–win attitude or motivation for both the contractor and the facility owner produced by and through the long-term relationship.

Use of federal funds

It is legal to use job order contracting when a project is funded, in whole or in part, with Federal Funds. The federal government uses the Federal Acquisition Regulation (FAR) to regulate acquisitions. Job Order Contracting is covered in the FAR in three key areas:

- Subpart 6 Competitive Requirements,

- Subpart 16.202 Firm-Fixed-Price Contracts, and

- Subpart 16.504 Indefinite Quantity Contracts

The American Recovery and Reinvestment Act of 2009, in section 1554, states that:

To the maximum extent possible, contracts funded under this Act shall be awarded as fixed-price contracts through the use of competitive procedures. A summary of any contract awarded with such funds that is not fixed-price and not awarded using competitive procedures shall be posted in a special section of the website established in section 1526.

JOC is a firm fixed-price, indefinite quantity contract that is competitively procured. JOC is ideally suited to accomplish work with stimulus funds because it expedites the procurement process, saves money and is completely transparent.

Issues

Competitive JOCs – So called “Competitive JOCs” are not reflective of LEAN and/or best management practices. The practice of awarding more than one JOC contract for one location and then bidding the contractors against each other on each job order. Owners have the idea that if two contractors compete against one another, they will get a better price. The way to avoid the problem of only having one JOC contractor is to award multiple JOC’s each having their own defined geographical boundaries. The work in a particular boundary will always go to the JOC contractor awarded that geographical area unless that contractor is failing to perform or is over committed. In that case the work could be given to another JOC contractor in an adjacent region. The goal is to never compete two JOC contractors on an individual project!

Attempting to compete multiple contractors on a JOC project is motivated by the following reasons:

- The owner mistrusts the contractor.

- The owner perceives that JOC can be a “win-lose” proposition (win for the owner and lose for the contractors).

- The owner does not understand the differences in performance by the contractors.

- The owner does not understand construction, construction management or facility systems.

- Someone within the owner’s management organization will receive recognition for reducing the short-term cost of JOC construction by forcing contractors to provide services with minimal or no profit

Open or Open Book JOCs – A unit price book (UPB) that accurately defines and prices unit line item construction tasks is a requisite component of JOC. Some Owners have allowed open or open book JOCs. In these cases, Contractors are allowed to get quotes from the open market and submit these prices in lieu of using a unit price book. This practice is also contrary to JOC best management practices and should not be supported. I

Capability – Neither all Owners or all Contractors are ready for JOC. Organizational support, technical and business capability, and a true desire for continuous improvement and information sharing MUST ALL be present.

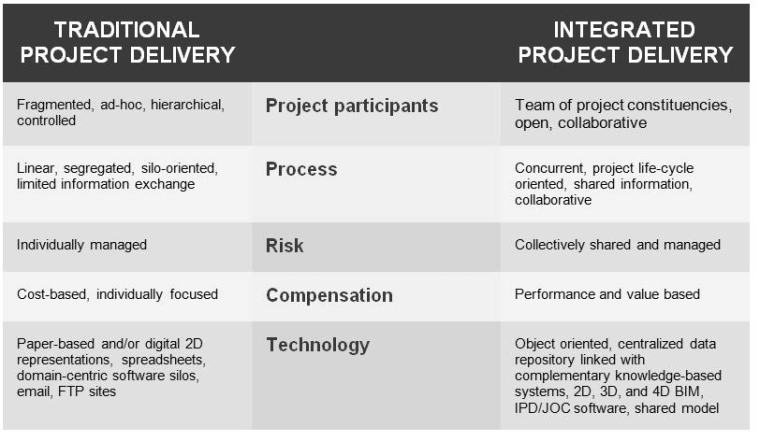

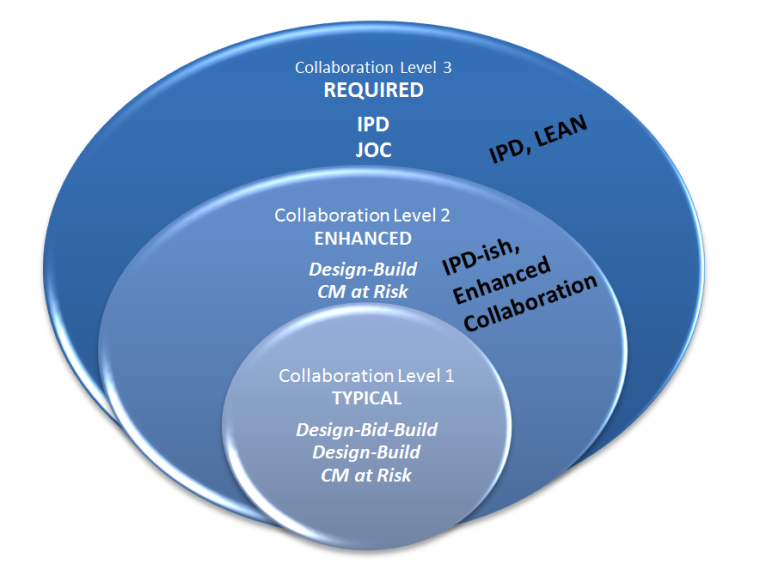

Integrated Project Delivery

JOC is a form of integrated project delivery (IPD) targeting renovation, repair, maintenance, sustainability, and “minor” new construction projects, while IPD targets major new construction. The below figures highlight the various forms of collaborative project delivery and their primary components.

Source: The above is adapted from open source content including Wikipedia, and also includes other source material/commentary.

References:

A Path Toward Construction Productivity – Academia.edu, July 2015

Emerging Technology Cloud Computing and BIM – American Military Engineers SAME TME, Pg. 59

Integrated Order Contracting, pg. 77 – TME – Society of Military Engineers]

Use of Few Models for Project Delivery Results in Missed Opportunities for Lowering Cost and Speeding Delivery, California Performance Review

Improving the Army’s Job Order Contracting Program, 1988