By Julia H. Schofield, PE, Sam S. Zalok, PE, and John N. Karras, PE

The practice of blindside waterproofing, where the membrane is pre-applied to an excavation support system outboard of the concrete foundation wall, has a decades-long history of use on commercial building projects, and yet it is not uncommon for contemporary projects to experience unwelcomed surprises at the time of a building’s waterproofing installation.

These scenarios can force the team to scramble and either reluctantly accept installation details that may compromise the intended performance or consider time-consuming or costly changes to the waterproofing or building design. In

this article, the authors highlight their experience with certain design decisions, site conditions, construction methodologies/materials, and service penetration configurations which are often disjointed variables that continue to be common sources of blindside waterproofing surprises. The authors provide recommendations for anticipating and integrating these variables into a coordinated blindside waterproofing design.

Support of excavation and foundation structural design

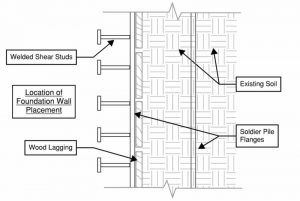

Support of excavation (SOE) is a common approach to enable the construction of below-grade building space. In addition to providing earth retention, the SOE serves as the substrate for the blindside waterproofing membrane, and the SOE structural features (e.g. tiebacks, bracing) that penetrate the waterproofing must be addressed with flashing details. Consequently, the SOE system and its features are integral to the blindside waterproofing system.

The final SOE design is typically delegated to the SOE trade contractor and their specialty engineer. The SOE delegated designers and the designer of the below-grade waterproofing system (e.g. the architect or their waterproofing consultant) seldom share an integrated design process; therefore, the SOE design may inadvertently incorporate features that create waterproofing performance vulnerabilities. Some of these features are summarized below:

Shear studs between soldier piles and the building’s structural foundation

Some structural foundation designs incorporate hundreds or thousands1 of shear studs welded to the SOE (Figure 1). The penetrations can be treated with the waterproofing manufacturer’s standard details, but they are costly and inherently increase performance vulnerability for the waterproofing by (a) creating permanent penetrations that rely on sealants/mastics to resist water leakage rather than a continuous membrane, and (b) reducing the margin-for-error by increasing the waterproofing system’s dependency on workmanship sensitive details.

Double waler seats or double knee-braces

Some SOE designs incorporate doubled-up waler seats or braces (Figure 2) in such close proximity to each other (e.g. 25.4 mm [1 in.] or less) that flashing sheets or sealants cannot be properly constructed in the space between the two. Sometimes project teams consider injectable waterstops, which in general can be helpful supplemental accessories for challenging below-grade waterproofing details, for these conditions. However, reliance on chemical grout injection from the waterstop inherently leaves the detail more vulnerable to water leakage than if the structural members are spaced (approximately 203.2 mm [8 in.] minimum apart) to allow the application of sheet flashing membranes that turn onto the structural member.

Impressive insights on mastering blindside waterproofing! Adopting a proactive and integrated approach is key to achieving long-lasting protection for below-grade structures. This article offers valuable knowledge for professionals in the construction industry.

This blog on mastering blindside waterproofing offers comprehensive insights into proactive strategies for integrated waterproofing solutions. It’s a valuable resource for construction professionals seeking to enhance building durability and performance against the effects of water damage.