While we love good intentions, the design of a high-performance building doesn’t mean much if it doesn’t operate at the performance standard it was designed to. All too often, building performance is the focus of the design phase but left to chance in operations. When controls programming and operational issues aren’t caught and addressed once a building goes online, it may lead to wasted energy and higher utility bills, as well as reduced occupant comfort and lower productivity.

This building performance issue is out of control(s)! The National Building Controls Information Program (NBCIP) studied the impact of building controls issues in 132 buildings and found that just because a building has a building management system (BMS) does not guarantee that it is programmed correctly and allowing the building to operate efficiently. The NBCIP uncovered $400,000 in potential annual energy savings for the 132 buildings studied, and 77% of the savings came from simply fixing control issues. Similarly, in Oregon dysfunctional direct digital controls (DDC) systems in K-12 schools resulted in a loss of $1 million in energy costs per year to the school system.

But these losses are avoidable. With data at the forefront of the industry, building performance can be closely monitored and continually optimized through Monitoring Based Commissioning (MBCx).

WHAT IS MONITORING BASED COMMISSIONING?

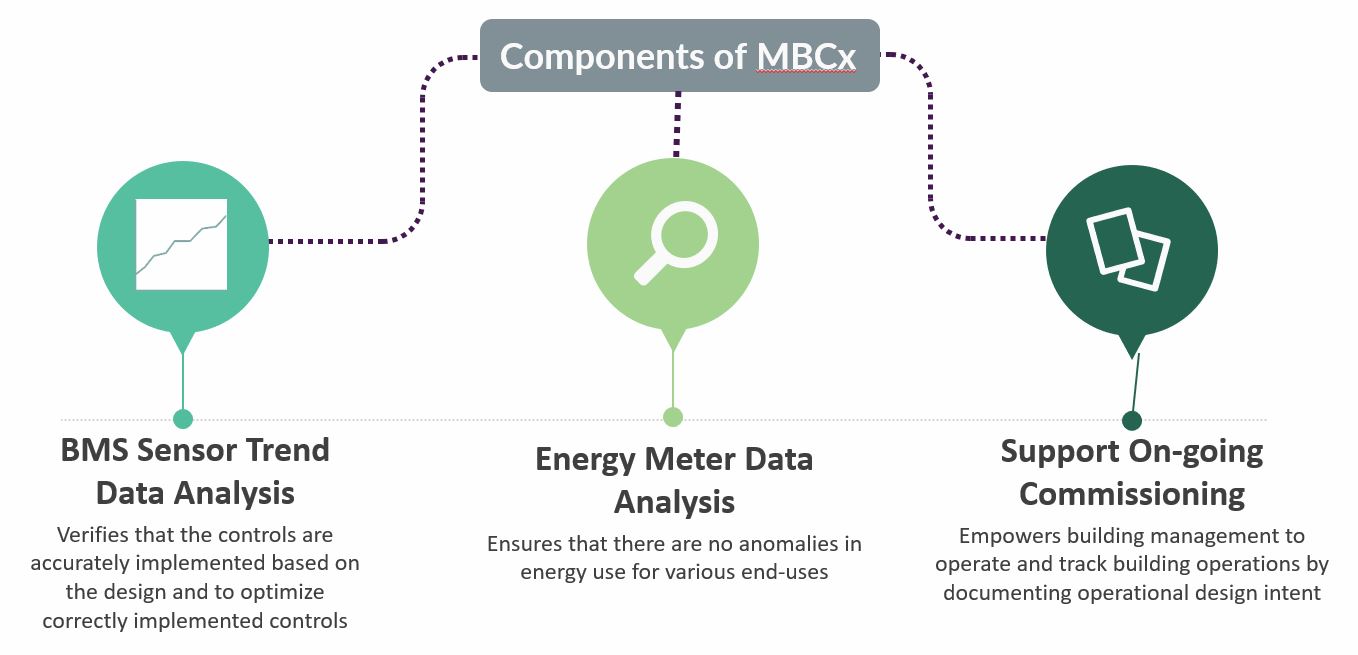

MBCx is a clear, comprehensive, data-based approach to verify that building systems operate according to the design documentation. It consists of BMS analysis, energy meter data analysis, and ongoing commissioning support.

HOW DOES MBCX DIFFER FROM CX?

They’re both commissioning, but MBCx works to complement general onsite commissioning (Cx). At a high-level, Cx focuses on system setup and MBCx focuses on system operation. While verification of controls is one important aspect of on-site testing during Cx too, verifying controls in all operational modes and observing the trends of energy consumption is not practically possible through Cx. For this purpose, project teams can pursue MBCx in the operations phase to confirm that the systems are operating per sequence of operations (SOOs) and further look for ways to optimize the controls. Hence, MBCx can catch operational deficiencies that, given its scope and timing, general Cx cannot.

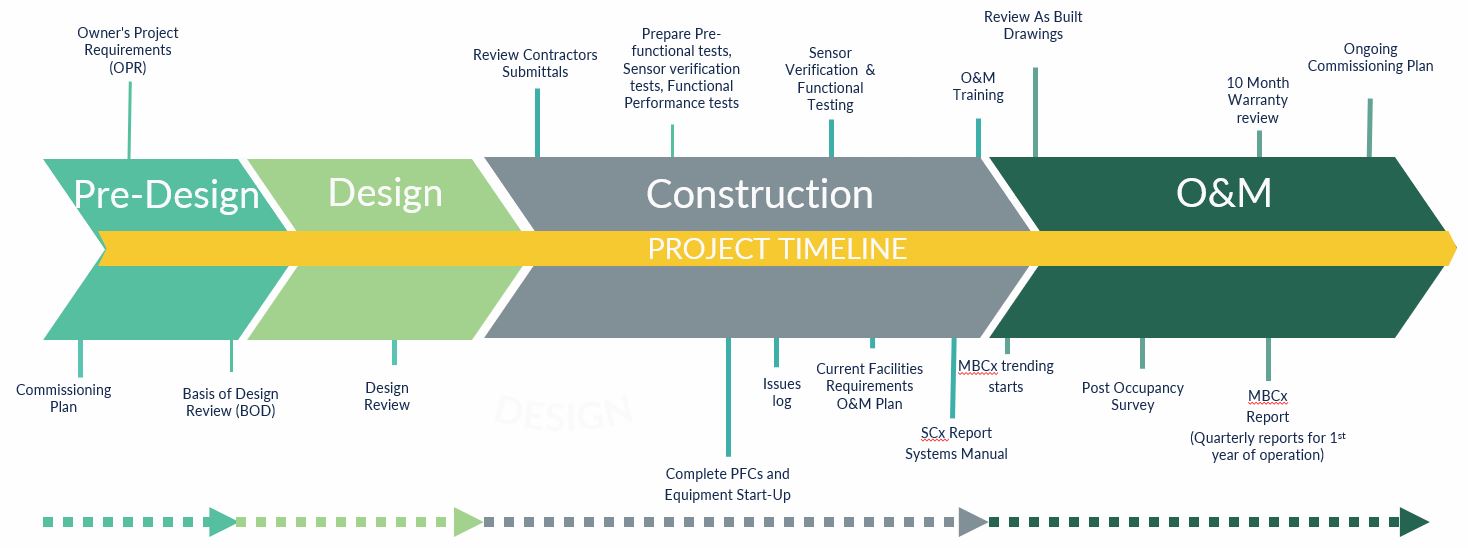

WHERE DOES MBCX FIT INTO THE PROJECT LIFECYCLE?

MBCx bridges the gap between the design and day to day operations of a building. For greatest impact, the process ideally starts as early as the pre-design phase, where the Commissioning Agent (CxA) ensures that the Owner’s Project Requirements (OPR) is captured. Through the design and construction phases, the CxA verifies that the design satisfies all the owner’s requirements and verifies that system components are selected and installed correctly. The operations and maintenance phase is where MBCx has the greatest project impact, with the chance to optimize the building’s ongoing performance through real time data analysis.

WHAT CAN PROJECTS ACCOMPLISH THROUGH MBCX?

The overarching goal of MBCx is to optimize building performance, which translates into energy and cost savings for the building owner and greater comfort for occupants (which also largely benefits owner-occupiers and tenants financially).

This is accomplished by first ensuring that the controls implemented through the BMS are accurate and operating correctly per SOOs, then by further optimizing the controls through MBCx analysis. By analyzing long-term operational patterns, MBCx can catch persistent sequencing errors that otherwise add up quickly. It discovers discrepancies that aren’t easy to see or feel and examines how different systems interact with one another. Speaking the language of the owner and/or occupant, MBCx can also quantify the energy losses and costs due to unideal performance and potential savings from optimization.

Key benefits of MBCx include the following, which can save energy and create a workplace that optimizes employee comfort and experience:

• Prevent issues such as simultaneous heating and cooling, inappropriate staging, or short cycling of equipment.

• Optimize systems performance that can result in energy savings by cutting unnecessary conditioning, implementing setbacks, or turning off systems during unoccupied periods.

• Improve occupant comfort by optimizing zone conditioning, managing carbon dioxide demand control ventilation, using smart start sequencing, or learning occupant behavior.

WHAT DOES MBCX LOOK LIKE IN PRACTICE?

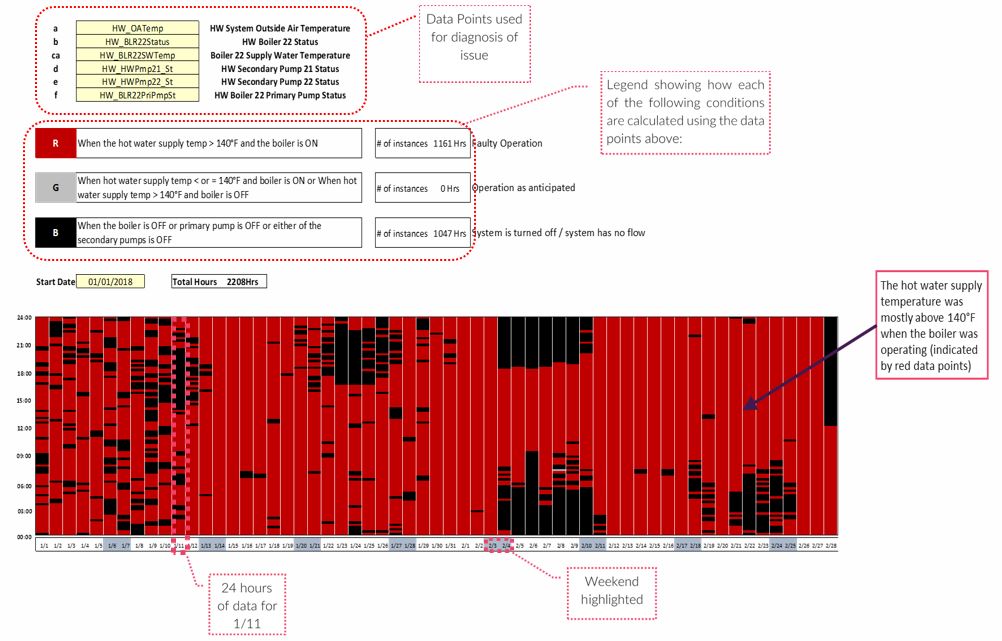

Applying the principles of MBCx, Stok helped optimize the operation of a building’s hot water system an office building. We looked at the hot water supply temperature control for a boiler in a building over a two-month time period and found that the boiler was providing water at a supply temperature higher than the setpoint for over 50% of the time, which was resulting in the system using approximately 30% higher energy than what was initially anticipated.

The heatmap graph below visualizes the data from this analysis. Each vertical bar in the visual represents data collected in one day. The data represented in red corresponds to the timesteps when the supply hot water temperature was higher than the set point and the data represented in black corresponds to the time steps when the hot water pumps remained off. Through MBCx, Stok caught this error by analyzing BMS data and helped the building’s facilities manager fix the issue to save energy.

Let’s take back control over performance across the entire building lifecycle, from concept through operations. To learn more about MBCx and how to implement it on one of your projects, contact our team.