Picture this: It’s early spring of 1959 in Hillsboro, Illinois. Winter’s gone, and Ralph Korte’s hard at work on the roof trusses of a future milking parlor. And he’s finding ways to build them better through the company bearing his last name.

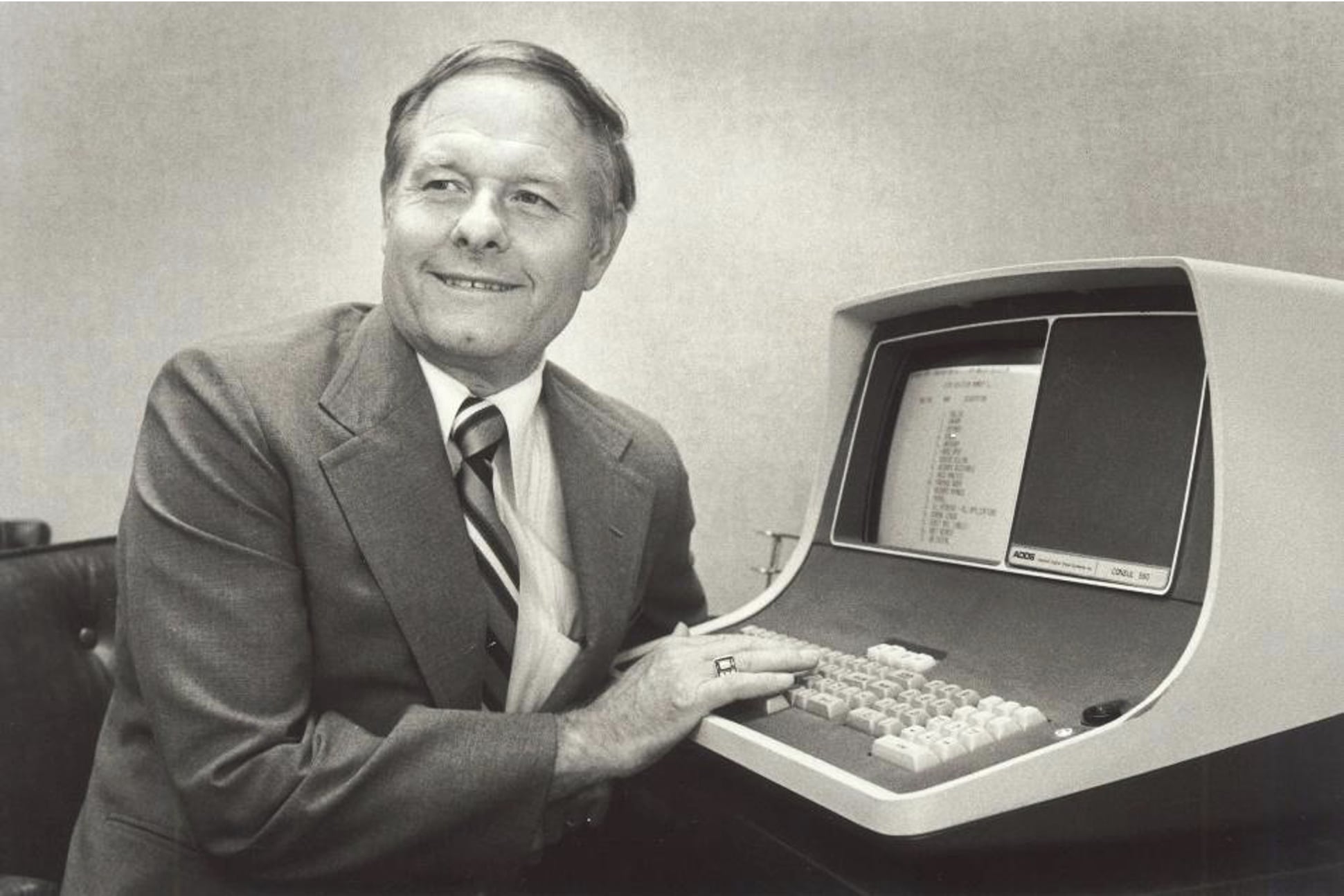

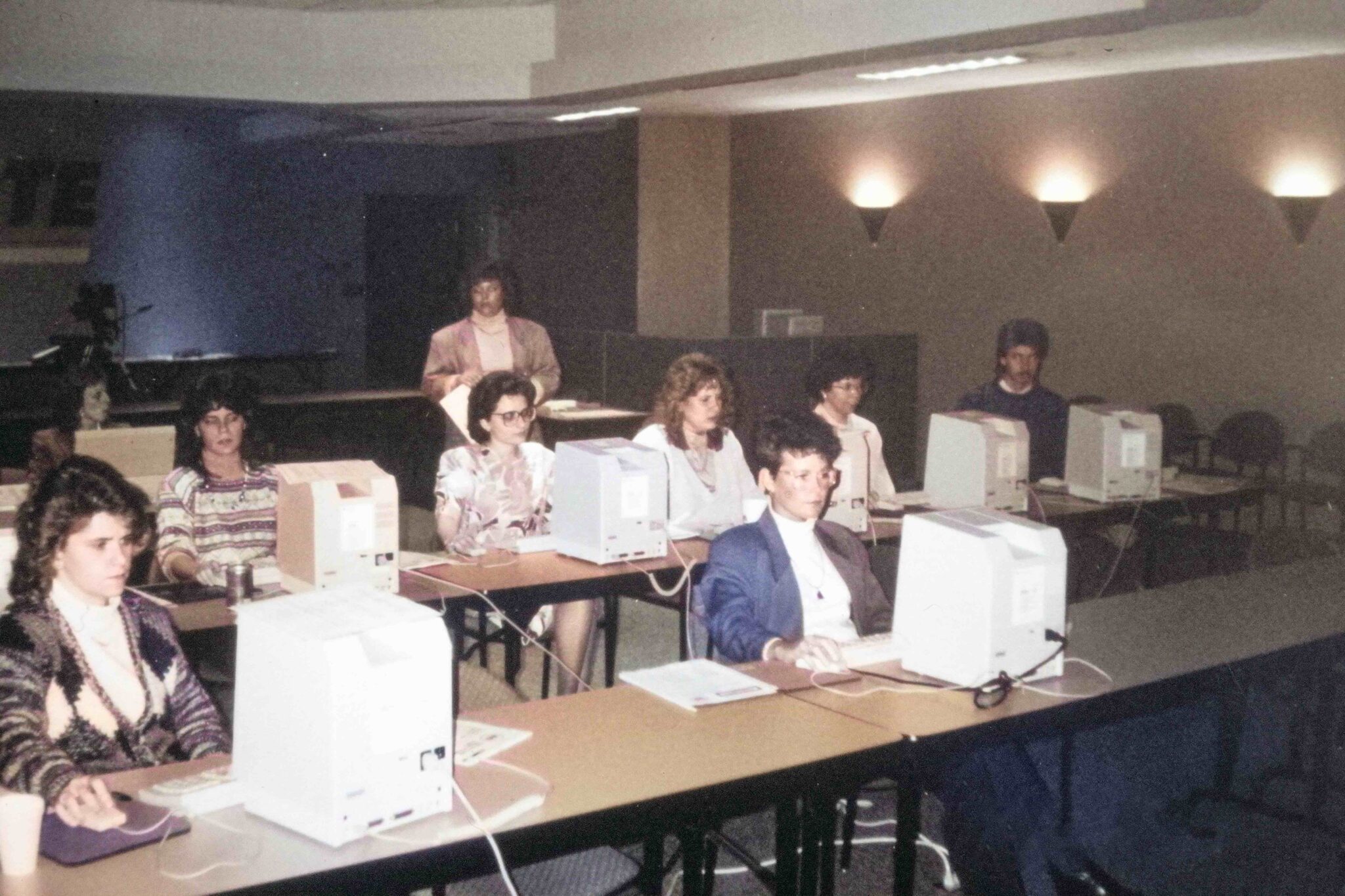

Fast forward to 1976. Ralph has found his footing in the construction world by keeping a keen eye on the future. The secret? It’s two-fold: honest hard work and embracing new technologies. Computers aren’t just for the sci-fi pictures anymore. They’re tools that any blue-collar working man can use. So, Ralph bought one for the office for estimating, scheduling and planning.

It was a bold move that set the stage for The Korte Company’s first technological revolution.

See, innovation isn’t a one-time thing for The Korte Company. We helped spearhead the development of the Design-Build Institute of America and the Design-Build method itself.

With the rise of our internal Design-Build division in 1977, we also pioneered Tilt-Up construction and won key projects for the USPS and distribution centers across America.

The embrace of Building Information Modeling (BIM) and LEED certification? Just another day at the office.

And that bold, innovative spirit? That’s still how we work. Our philosophy has always been about finding the best way to build smart, then building upon lessons learned.

The new frontier: AI in construction

We don’t want a Korte where robots have taken good jobs away from good people. But we do want to know how AI make us smarter, safer and more cost-effective on future projects.

That’s why we have an AI team working on an ambitious, secure in-house language model. Eventually, we hope it will help us summarize and sift through mountains of RFI and RFP information during pre-construction, trimming back on the tedium that can slow us down. So instead of a time-consuming dig for answers, employees could just ask the platform questions, and the AI would answer as easily as a well-informed assistant.

As we see it, AI can flatten unnecessary speed bumps in the lifecycle of a job, accelerating our time to completion. And that’s a good thing for our customers and for us.

The potential isn’t just limited to dense stacks of paperwork. In many ways, the genius of predictive language models is already here. When a project manager starts drafting an email, intelligent software suggests the words that finish a sentence — shaving down the time needed to finish the message.

Sure, shooting off fast responses to team members is small, but that’s part of the beauty. Those small moments add up to real dollars saved.

Not broken, but we can make it better

For years, we tracked jobs through in-person job walks, phone calls, text messages, email and field reports. And for years, those techniques worked just fine.

But it can be slow — especially as evolving technologies in other areas of our lives have heightened our expectations for the instantaneous.

Always keeping our eye on the future, we’re exploring new ways to do things.

For example, we can integrate cameras through software like OpenSpace to document and track project progress. 360-degree images help us capture and share progress for comprehensive updates to clients and stakeholders, who “walk” jobs through the digital model, turning left and right, and looking up and down. No huge emails. Easy collaboration. And these interactive experiences save on travel time and expenses.

We also expect these types of programs to eventually help us reduce rework by seeing what can’t be seen — such as clash detection issues. This ultimately reduces schedule delays, helping The Korte Company win more work that simply pays for itself.

We also expect software we already depend on, like Autodesk and Revit, to naturally incorporate AI into its software.

Bionic exoskeletons hit the commercial market a few years ago, promising to reduce fatigue and injury for construction workers. As AI evolves, we hope for ways to incorporate this new technology into our safety program. For instance, wearables and devices that can track movement could ensure workers avoid restricted zones and don the right safety gear.

A safer workplace made possible through technology? We tip our hard hats to that.

Slow and steady toward the future

From streamlining operations to optimized pricing to faster project completions, AI clearly has its advantage. But with great potential, there’s also newfound responsibility.

Data privacy, bias, reliability. It’d be foolish to jump in without considering the risks. And even when we dream big, like incorporating AI to optimize design, we must also step back and ask ourselves who takes the blame if AI makes decisions with safety or legal consequences.

Like any new tool for the job site, The Korte Company is only approaching AI with an intentional, calculated approach. It’s about education, pilot projects and leaning on our team of tech experts to build an implementation plan that makes sense and fits our values.

It’s about following our own legacy of smart, intentional innovation.

From where we stand, AI’s possibilities seem limitless. It’s thrilling. Maybe a little scary. But we have a plan. And it’s rooted in our drive to always build smarter. Just like Ralph always did.