by Dave Ross

Concrete has been used for thousands of years and is the most widely employed building material in the world. According to the Cement Association of Canada (CAC), more than twice as much concrete is used in construction around the world than the total of all other building materials, including wood, steel, plastic, and aluminum.

Yet, despite its apparent solidity, strength, and durability, concrete is porous. It is also and permeable to fluid and vapor infiltration and migration. Water and dissolved chemicals, such as chlorides, sulfates, and acids, can penetrate deep into concrete, sometimes resulting in premature damage, such as reinforcing steel corrosion, freeze/thaw cracking, spalling, and chemical attack.

Added to this ‘natural’ porosity is the fact newly poured concrete develops cracks. This can be due to excess water, rapid drying, improper strength, settlement, and shrinkage. When it comes to building foundations, elevator pits, water/wastewater treatment and water containment structures, and many other applications, waterproofing and protecting the concrete is critical.

The porous and permeable nature of concrete

Concrete is a mixture of rock, sand, cement, and water. Rock and sand form the aggregate base of the concrete. The mixture of the cement and water provides a paste, which binds the aggregates together. As the cement particles hydrate and form calcium silicate hydrates, the whole mixture hardens into a solid, rock-like mass.

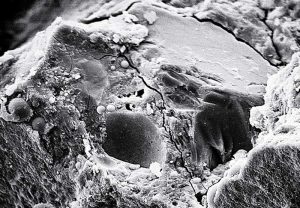

To make this mixture workable, easy-to-place, and consolidate, more water than necessary is used to hydrate the cement. This extra water, known as the water of convenience, bleeds out of the concrete, leaving behind pores and capillary tracts.

Despite the use of admixtures to reduce the amount of water in the mix, pores, voids, and capillary paths still form in concrete. These pathways carry water and aggressive chemicals that can corrode steel reinforcement and deteriorate the concrete, thus jeopardizing the structure’s integrity.

Porosity

Porosity is the amount of holes or voids left in concrete, expressed as a percentage of the total volume of a material. Since it is porous, concrete is also permeable.

Permeability

A broader term than porosity, permeability is an expression of how well the voids are connected, providing the ability of water to flow through a material. Together, these pathways allow the movement of water into and through the concrete. Permeability is described by a quantity that is known as the ‘permeability co-efficient,’ also called Darcy’s Co-efficient. The water permeability of concrete is a good indicator of its quality and durability. The lower the permeability co-efficient, the more impervious the concrete and the higher its quality and performance. Nevertheless, concrete with low permeability may still need a waterproofing agent to seal micro-cracks.

It is possible to reduce the permeability of concrete with certain admixtures. These admixtures can be divided into three categories per the American Concrete Institute (ACI) 212.3 R-10, “Report on Chemical Admixtures”:

- hydrophobic or water repellent admixtures;

- mineral fillers such as talc, bentonite, and clays; and

- crystalline admixtures.

Vapor flow in concrete structures

Water can also migrate through concrete in the form of vapor. The flow travels from high vapor pressure, generally the source, to low vapor pressure by a process of diffusion and can vary based on environmental conditions.

Vapor flow direction is critical when applying a waterproofing treatment in situations where an unbalanced vapor pressure gradient exists. Some typical examples of this are as follows:

- applying a low vapor permeable membrane, such as a traffic deck coating over a damp concrete surface (even if the very top surface is dry) on a warm day results in vapor pressure buildup and pin-holing or blistering;

- adding a coating or sealant to the outside of a building wall may trap moisture if the sealant is not sufficiently vapor permeable; and

- installing low vapor permeable flooring over

a slab-on-grade with high subsurface moisture content may result in delamination.

As a general rule, a coating with low vapor permeability should not be placed on the downstream face (negative or dry side). Either vapor or water pressure will ‘push’ the coating from the surface, causing it to blister. Some types of coatings (e.g. cement-based ones) and water permeability-reducing admixtures accommodate considerable vapor movement, thus allowing them to be placed successfully on the downstream side.

Very cleared position of concrete waterproofing.must be read

HOW DO YOU TREAT A LEAKING ROOF?