By John C. Stuart and Christopher N. Grey

When specifying fenestration, design professionals must select appropriate products for the project’s various opening sizes. However, today’s construction landscape is rapidly changing with higher material costs, tight tolerances, and expectations of floor-to-ceiling glazing in multifamily projects (Figure 1).

Many project teams are opting to specify delegated design mulled window systems that combine multiple windows into a single unit in a larger glazed opening, rather than a storefront or curtain wall system. While these mulled systems have become increasingly popular, their mulling components can create potential performance issues, including air infiltration, water penetration, structural failure, and reduced thermal performance.

Highlighting examples from past projects, this article explores the rationale and risks of using mulled window systems; reviews methods for addressing these risks; and demystifies standards, such as NAFS-17 and AAMA 450-20, that are crucial for design professionals specifying window performance.

Fenestration: A performance perspective

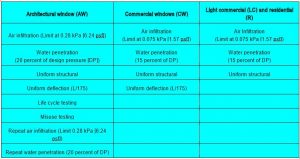

AAMA/WDMA/CSA 101/I.S. 2/A440-17, commonly known as the North American Fenestration Standard or NAFS-17, defines window ratings based on air infiltration, water penetration, and structural (AWS) performance during laboratory testing.1 Rated products are assigned a performance class (R, LC, CW, and AW), with R (residential) windows having the least rigorous testing requirements, and AW (architectural window) having the highest and most diverse requirements (Figure 2, below). Products also carry a performance grade, indicating the maximum wind pressure that product has been tested to, without unacceptable deflection or damage. Water penetration resistance is also tested at a fixed fraction of the structural pressure, typically 15 or 20 percent, depending on the performance class. This system is widely used by window manufacturers throughout North America so designers can compare and specify window and door products.

A window product line is typically tested only up to a size determined by its manufacturer that minimizes the frame depth and weight while optimizing for the most common residential opening sizes. Unfortunately, this optimization for smaller openings means the most widely available and economical products often do not have the stiffness to achieve the nearly floor-to-ceiling spans expected in many recent multifamily projects. In this scenario, many designers turn to storefront and curtain wall systems specifically designed for such spans. However, if the project’s design intent or budget do not allow for these systems, window manufacturers frequently propose a mulled window system as a solution.