It is hard to imagine any urban setting without parking garages. Given the limited availability of usable areas in busy cities, parking structures efficiently provide stalls for vehicles in airports, train stations, bus stations, commercial buildings, hospitals, and malls. They are commonly built using cast-in-place concrete, precast concrete, post-tensioned concrete, structural steel, engineered lumber, or a combination of these systems. Structural parking decks typically consist of reinforced concrete slabs over precast supporting units. The initial slopes of the slabs along with their structural deflections are important to direct water toward the drains as per the building’s water management plan.

Surface protection and insulation

Parking decks are costly to build, repair, and replace. Water is the major cause of concrete deterioration and steel rusting, so its management is vital to ensure proper durability. Designing, installing, and testing specialized systems are key steps to ensure water is diverted away from the deck’s structural elements. The waterproofing layer can be placed on top of the deck system where it is easy to inspect and repair; however, the layer is not secured against pedestrian and vehicular traffic. The preferable approach to parking garages is to use a protected waterproofing membrane. As the name implies, the membrane will be protected from traffic, which can extend the service life of the deck. Nonetheless, the limited accessibility will make the assembly hard and expensive to maintain. Loose-laid membrane can also be applied, but full adhesion is the most common application of deck membrane.

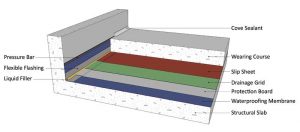

The adhered system can be achieved through cold, hot, or sheet application. However, challenges with maintaining thickness and quality through cold and hot adhesion makes rolling out premanufactured rubberized asphalt membrane the most common application. The sheet membrane has many joints which may leak water if they are not sealed tightly. Creating a continuous plane throughout the deck—especially around penetrations—is essential for watertightness. Flashing and pressure bars are used to maintain membrane continuity at terminations. Cracks plus expansion and construction joints in decks require special attention and consideration. Regular inspections and timely repairs are vital to maintain healthy buildings. The structural behavior of the floor slab, including deflection values and locations, affects the performance of the waterproofing system.

The typical parking deck comprises a waterproofing membrane adhered to the top of the structural slab, drainage grid, and wearing course (Figure 1). This assembly works like a rainscreen exterior wall, as most of the water trenches over the wearing surface, while some finds its way onto the waterproofing membrane and moves toward drains through the drainage grid. Therefore, the topping acts as a membrane protector and water shedding layer—just like siding on walls. Other layers such as protection boards, insulation, and slip sheets can be added to improve overall performance and durability.

An insulation layer within a deck assembly is crucial when it separates two spaces with a wide difference in temperature, such as a parking floor and an air-conditioned/heated living space. Similarly, in cold climates, the lack of insulation (thermal barrier) below a plaza deck and above a heated parking space can cause condensation issues on the exposed bottom surface of the concrete deck. In contrast to a deck separating two parking floors, a plaza deck is a supported slab which provides green-scape and tree planters in addition to pedestrian vehicle loads over an occupied space. Special considerations should be given to the design and construction of waterproofing systems for plaza decks.

Unlike fully shielded buildings, parking garages are mainly open to the elements. Therefore, their concrete surfaces are more prone to deterioration, such as spalling, scaling, cracking, and delamination. These structures are also subjected to dynamic loading conditions and destructive chemicals from de-icing materials, as well as mechanical abrasions from cleaning and snow removal equipment. Functional maintenance and repair programs are important to extend the service life of the structure. In general, a full comprehensive condition review must be conducted by an experienced engineer at least every five years, or when there are signs of structural and performance issues.

Looking forward to including the specifier as a resource to our office library.