Over a third of workplace hand injuries involve cuts and often occur because workers are wearing the wrong hand protection — or worse, no hand protection. Unfortunately, the countless options on the market can make it difficult to choose the right cut-resistant gloves.

So, how do you select safety gloves that will protect your workers’ hands from sharp objects without inhibiting their performance and comfort? The top two considerations we will discuss in this article are:

- Glove-shell material

- Cut resistance protection level

Glove-Shell Material

The two primary materials used to manufacture cut-resistant gloves are made from high-strength synthetic fibers:

- High performance polyethylene (HPPE) — Soft and cool to wear, more dexterous and with a higher tactile feel than para-aramid, but will melt under heat

- Para-aramid — Naturally flame resistant, but is a dense fiber and is warmer to wear than HPPE

Gloves made solely with HPPE or para-aramid can offer up to American National Standards Institute (ANSI) Level A3 cut resistance but, thanks to engineered yarn, additional materials can be added to achieve higher cut protection and improve dexterity, comfort and durability. These added materials can include one or more of the following:

- Steel, metal wire or fiberglass to enhance cut protection, but reduces glove dexterity

- Nylon and polyester to enhance comfort and dexterity

- Cotton to enhance comfort

Metal can also be used as the only material in cut-resistant gloves. Gloves made with metal are called chainmail and are primarily used in food processing for deboning meat.

Now that you know the common materials that provide cut resistance, how do you decide which level of cut protection to buy?

Cut Resistance Protection Levels

There are industry standards established that refer to specific test methods to assign protection levels for safety gloves, including cut resistance. These standards specify certain tests in which the force it takes for a blade to cut through the material is measured.

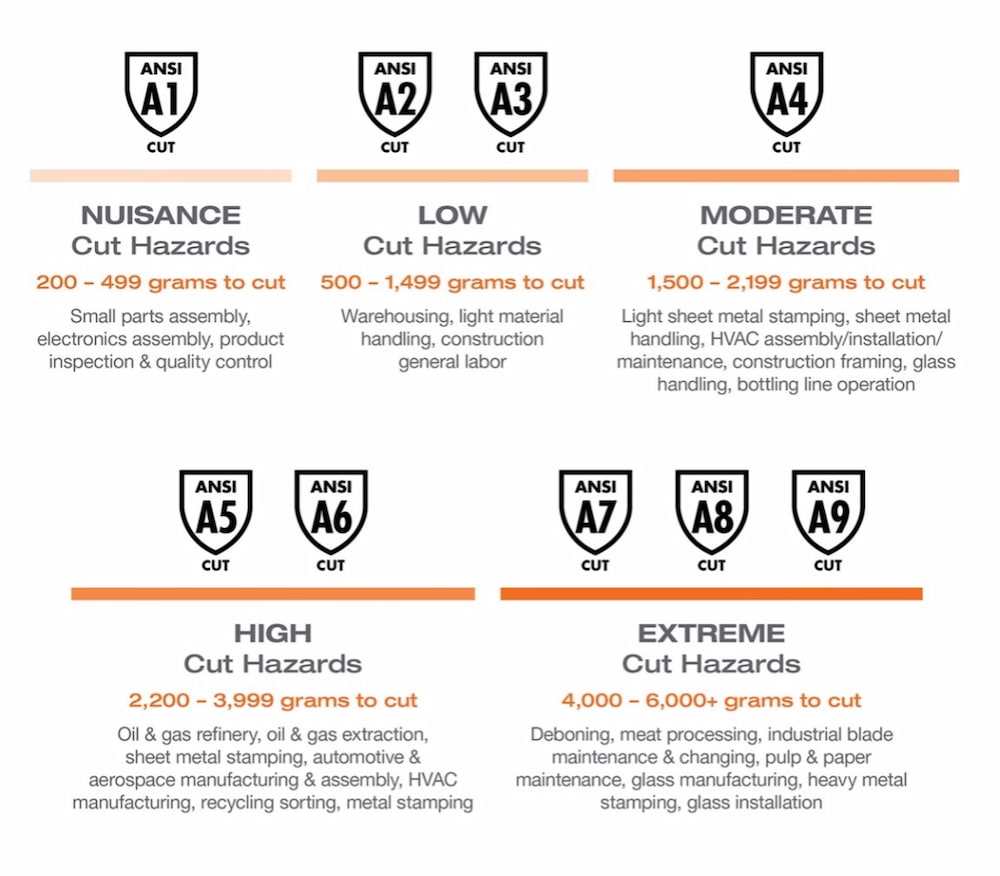

The most recognized standard in North America is the American National Standard for Hand Protection Classification, ANSI/ISEA 105. This standard established the ASTM F2292-15 test method for measuring cut resistance and identifies nine cut levels (A1-A9), ranging from 200 grams to 6000+ grams of cut resistance.

Figure 1 shows a general breakdown of cut hazard protection as it relates to each level.

Generally, low cut-resistance levels (A1-A3) provide protection against minor nuisance cut hazards found in lower-risk environments, such as in a warehouse where workers are handling boxes. Cut-resistance levels of A4 and above are better suited for applications where cut risks are much higher, like handling glass sheets, metal press work, or heavy assembly. However, ultimately, the task and risk level of the hazard determines the cut protection level required for the job.

Learn More

There are other important factors that contribute to glove performance and selection of cut-resistant gloves. To learn more, we’ve created a comprehensive guide that expands on the ins-and-outs of cut-resistant gloves, including the underlying forces at work and the significance glove gauge and palm coatings have on cut resistance. We’ve also clarified some misconceptions around cut-resistant gloves. Click here to read.

Sponsored by