The new French environmental regulations position natural materials as a priority for a sustainable future in construction, in both housing and public buildings. Wood, straw, hemp, reed or bamboo, in combination with earth or stone for their high thermal inertia, offer virtuous alternatives to the use of cement.

Straw-bale construction was developed in the 1880s by settlers on the North Central Plains of the United States. In the absence of traditional building materials, they stacked hay and then straw bales to build the load-bearing walls of their homes, implementing the so-called ‘Nebraska technique’.

Straw-bale construction was developed in the 1880s by settlers on the North Central Plains of the United States. In the absence of traditional building materials, they stacked hay and then straw bales to build the load-bearing walls of their homes, implementing the so-called ‘Nebraska technique’.

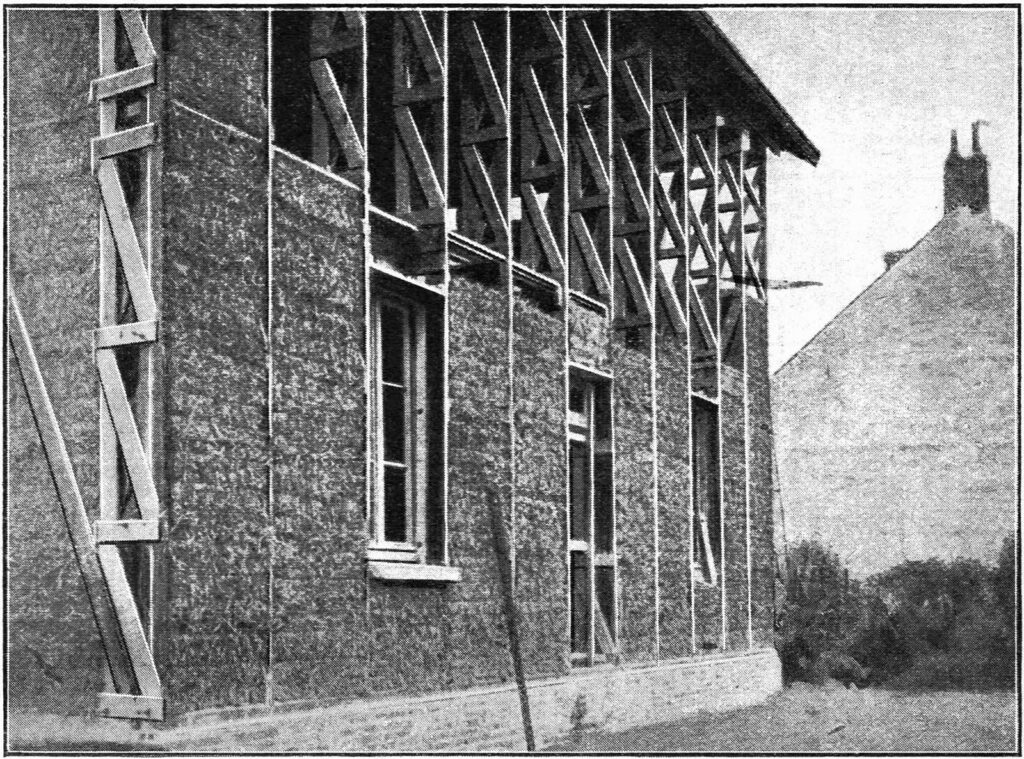

The oldest known existing wood-frame building with straw insulation in France is the Maison Feuillette in Montargis. Built in 1920, this small house with a gable roof is a symbol of the durability of this technique. It was designed by the engineer Émile Feuillette with the aim of creating a home that was economical and quick to build. In this period of postwar reconstruction, materials were scarce. He therefore used small timber sections for the load-bearing framework of oak and poplar lattice beams, and filled them with straw bales for insulation. The layout of the wooden structure avoided cutting the bales to save material and time.

The oldest known existing wood-frame building with straw insulation in France is the Maison Feuillette in Montargis. Built in 1920, this small house with a gable roof is a symbol of the durability of this technique. It was designed by the engineer Émile Feuillette with the aim of creating a home that was economical and quick to build. In this period of postwar reconstruction, materials were scarce. He therefore used small timber sections for the load-bearing framework of oak and poplar lattice beams, and filled them with straw bales for insulation. The layout of the wooden structure avoided cutting the bales to save material and time.

Since the Paris Agreement in 2015 and the 2019 Energy-Climate Law, the French government has sought to reduce GHG emissions by facilitating the uptake of low carbon technologies, products, processes and services in sectors with high energy-saving potential. The building sector is responsible for about 40 per cent of the country’s GHG emissions. In force since 2021, the law promotes bio-based materials, which are abundant in France: it is the leading producer of straw and hemp in Europe, and the sector has an important potential for job creation, especially in rural areas. Straw is an agricultural by-product of wheat production, often burnt as waste. Around 25 million tons are produced every year: 10 per cent would be enough to insulate 500,000 dwellings per year.

Ten years ago, there were approximately 500 buildings insulated with straw in France, and most were self-built houses. In 2022, there are more than 6,000, including hundreds of public buildings. There are several construction techniques: filling in a frame or prefabricated timber cassettes is quite common, while load-bearing walls made of superimposed straw bales are rarer, but could become more common with the increasing price of wood.

In 2012, a fire test took place on a facade prototype with a timber frame, straw infill and wood cladding. The test confirmed that, when compressed in the bale, straw cannot burn, as there is a lack of oxygen.

Two other buildings were central to the early development of straw construction and they were both built out of prefabricated timber cassettes with straw infill. One is in the hot Mediterranean climate, the other in the much colder north-east of France. In both cases, the thick straw bales assure thermal comfort in summer and winter.

Public facilities in wood and straw are increasingly common, especially in Paris and its surroundings, where the resources are easily available. Several schools have been built in the past decade using the timber frame with straw insulation technique. Opened in 2019, the Jacques-Chirac leisure center accommodates 180 children after school and during the holidays. To reduce the amount of wood needed, the two-story north facade and gables are made of load-bearing straw bales with lime-sand finish on the outside and earth-plaster on the inside. The bales have a very high density and they are laid flat, cross-jointed in corners and on long walls. To limit the risk of walls buckling and plaster cracking at the junction between bales, these are planted on chestnut stakes fixed in a thin wooden cassette. The traps that are passed under this base are used for tightening during the compression phase.

Public facilities in wood and straw are increasingly common, especially in Paris and its surroundings, where the resources are easily available. Several schools have been built in the past decade using the timber frame with straw insulation technique. Opened in 2019, the Jacques-Chirac leisure center accommodates 180 children after school and during the holidays. To reduce the amount of wood needed, the two-story north facade and gables are made of load-bearing straw bales with lime-sand finish on the outside and earth-plaster on the inside. The bales have a very high density and they are laid flat, cross-jointed in corners and on long walls. To limit the risk of walls buckling and plaster cracking at the junction between bales, these are planted on chestnut stakes fixed in a thin wooden cassette. The traps that are passed under this base are used for tightening during the compression phase.

Two new professional rules are also in preparation: one for walls with load-bearing straw bales, the other for the use of straw bales for external thermal insulation.

Although straw is readily available – and a carbon sink – the use of concrete, steel, polystyrene and mineral wool still predominates in France, due to the power of lobbies and well-established practices. However, the construction industry is concerned about increasingly restrictive regulations, and fears that its markets are slipping away. About 500 straw buildings are already realized every year and the trend is strongly upwards. Step by step, the sector is advancing thanks to benevolent regulations and a growing number of committed and competent professionals.

You can read the original article at www.architectural-review.com