by Rob Haddock

Rooftop avalanches cause property damage to the tune of hundreds of millions of dollars, personal injury, and death each year. A snowpack can suddenly release and dump tons of snow below the eaves in a matter of seconds, endangering building elements, adjacent roofs, landscapes, vehicles, property, and, even worse, pedestrians. This is clearly a life/safety concern.

Inadequate snow guard systems—or the lack of them—can potentially create liability issues for building owners, designers, and contractors.

Liability concerns

While engineered snow retention systems complement the roof, this market space is unregulated. Snow guards are not governed by codes or standards. Many applications are not specifically engineered for design loads. The only policing within this field is by the architect, specifier, and, too often, the contractor.

Plan callouts stating, “furnish snow guards, typical,” or specification language noting, “…as recommended by manufacturer,” is just rolling the dice, making the contractor the ultimate decision-maker for adequacy and product selection. If the system is devoid of appropriate design and testing it can fail even when installed per the manufacturer’s instructions, thereby exposing the designer and/or contractor to liability. System failure can threaten anything on the ground below and also damage the roof. Protection from this liability starts long before the project is bid.

Rooftop avalanche causes

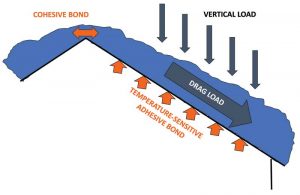

During snowfall, sunlight is occluded, and snowpack is retained on the roof by two bonds between the snow blanket and the roof. The first is a strong, but temperature-sensitive, adhesive bond between the blanket of snow and the roof surface. The second is a cohesive bond at the ridge where snowpack on one plane of the roof interlaces with snowpack on the other (Figure 1).

A vertical load (weight of snow) is added to the roof surface, which translates to a vector load parallel to the roof surface, often referred to as “drag load” or “gravity load”—the force of snow trying to slide off the roof. A rooftop avalanche occurs when vector forces exceed the strength of the two bonds on a slippery roof.

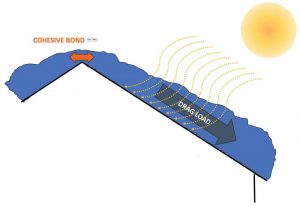

Infrared rays from the sun pass through the translucent snowpack, warming the roof below and freeing the temperature-sensitive bond. The meltwater lubricates the interface at the roof surface. (Since the snowbank insulates the roof, this happens even when ambient temperatures are well below freezing.)

The vector force of the snow blanket is now resisted only by the cohesive bond at the ridge, which is too weak, thus causing the blanket of snow to split leading to a sudden release of snow from the roof. This can happen on one side of the ridge or both simultaneously, depending on orientation of each to the sun (Figure 2).

Site-specific variables

A snow guard is a device or system that mechanically provides a resistance interface between the roof and the snow, so snow evacuates the roof in a predictable and controlled fashion—through evaporation (sublimation) and thaw rather than by a sudden and dangerous rooftop avalanche. The resistance of the snow guard system must exceed the vector force in service, otherwise it will fail.

The vector force applied to a snow guard system is a relatively simple calculation but varies with site specifics, such as:

- design roof snow load;

- roof slope; and

- roof (rafter) length from eave-to-ridge (Figure 3).

These three variables determine the force a system must resist for any slippery roof surface and should be included in plans and specifications that require an engineered system (for more information, read the Metal Construction Association’s [MCA’s] technical bulletin on “Metal Roof Design for Cold Climates”).