By Jeff Bowlsby, CCS, CCCA

A Portland cement-based plaster (stucco) wall cladding system inherently includes its perimeter edges—where the stucco simultaneously begins, ends, and interfaces with other claddings, structural elements, penetrations, and dissimilar materials. How the stucco panel edge condition is designed and constructed critically impacts the function, performance, serviceability, durability, and aesthetics of the stucco cladding as a system, which is not widely recognized or appreciated. The casing bead, as an integral part of the stucco panel edge joint, is the second most misunderstood and misused lathing accessory after the stucco control joint. The need, essential considerations, and requirements for the effective design and installation of stucco casing beads will be presented and discussed.

History and development

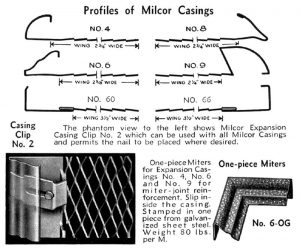

The stucco trade has used several different names for the casing bead over the decades, such as J-mold, J-metal, Milcor (Milwaukee Corrugating Co.), plaster stop, termination, ground, No. 66, or just 66. Depending on whose scaffold one is on, and what region of the country one is in, these names will be interchangeable and generally refer to the same lathing accessory. The term ‘casing bead’ is presented here for consistency with the nomenclature in ASTM International industry standards, which is also consistent with most manufacturers’ product literature.

When stucco began to be used for the exterior plastering of buildings in the late 1800s, no lathing accessories existed. L.E. Curtis patented the first casing bead in 1922. It had a key attachment flange similar to the casing beads of today and a solid metal ogee profile for the panel edge. It also had a decorative quality, which is generally missing in present-day casing bead products.

Milcor was a prolific manufacturer of lathing accessories in the early 20th century which listed its products as numbers. The Milcor casing bead was available in several different profiles, each with its own number. Milcor casing bead No. 66 is the same profile today as it was nearly a century ago. Other manufacturers may have had their own lathing accessory numbering system for similar products.

Requirements in building codes and industry standards

Casing bead requirements in ASTM C1063

A primary function of the casing bead is to separate the plaster from dissimilar materials as described in ASTM C1063, Standard Specification for Installation of Lathing and Furring to Receive Interior and Exterior Portland Cement-Based Plaster. The most up-to-date text reads, “install a casing bead lathing accessory or other suitable means, at locations to separate cement plaster from dissimilar materials.”

A great overview; I wish it had been available when I became an architect, or even later, when I became a specifier!

I am an owner builder in the San Diego area. I would like to know the casing manufacturers of the casing types that were discussed on the last page of your article

Al’s Can you refer me to or provide a spec that I can use in the bid process.