Chicago Union Station Great Hall Restoration

Chicago

Best Project and Project of the Year Finalist

Owner: Amtrak

General Contractor: Berglund Construction Co.

Lead Design Firm: Goettsch Partners

Structural Engineer: Klein & Hoffman

M/E/P Engineer: ESD

Chicago Union Station has long been recognized as a city landmark, but in recent decades the expansive skylight in the station’s Beaux Arts-style Great Hall suffered water infiltration damage and drainage challenges. Over the years, previous patch repairs altered the appearance of the skylight and the Great Hall, including decreasing the amount of natural light in the space.

A $22-million, 600,000-sq-ft restoration project led by general contractor Berglund Construction and architect Goettsch Partners restored the original skylight and protected it with the addition of a new exterior skylight to prevent water leakage and reduce maintenance needs.

By the time the project was completed in December 2018, crews had replaced all 2,052 pieces of wire embedded glass with transparent glass. The new exterior skylight features 858 panes of clear, high-efficiency glass, installed 5 ft above the historic skylight. The new system is expected to improve natural light in the space by nearly 50%.

The interior finishes—including paint, plaster and sculptures—were restored to their original appearance, as designed by Graham, Anderson, Probst & White and first viewed by the public in 1925. Historic lighting was also upgraded to help showcase the renovated space.

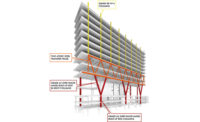

Access to the 219-ft-long barrel-vaulted skylight, which reaches 115 ft above the floor, was particularly challenging, says Mike Clarahan, project manager at Berglund Construction. The team had to be mindful that while skylight work was taking place, an estimated 130,000 Metra and Amtrak commuters could pass daily through the Great Hall directly below. The team chose to install a suspended deck system below the entire existing skylight. The system hangs from the skylight’s structural steel beams, so no scaffold legs extend to the floor. To access the walls high above the hall, the team used swing stages.

Other areas of the building were accessed with more traditional scaffolding to access ceilings and walls in the breezeway, stairways, the mezzanine and balconies.

Clarahan says the team used 3D modeling, especially in the early stages, to help all parties better understand the project. “It was particularly effective for communicating to the owner what [the scaffold] was going to look like,” he says. “Trying to describe a suspended deck with swing stages to anyone can be pretty complicated.”

Roughly 75,000 sq ft of wall area was painted during the project and about 37,000 sq ft was skimmed with new plaster or repaired. While early investigations uncovered areas of the walls and finishes that needed repairs, crews often discovered additional damaged areas. “Sometimes we didn’t know until we got up on the wall and the painters started scraping,” Clarahan says. “If they came across any loose plaster, we would swap crews and do plaster demolition.”

Clarahan says Berglund communicated with Amtrak daily about its plans, including how best to provide protection to the public. Procedures were established and a chain of contact personnel was created.

Clarahan says crews installed and removed the suspended deck during off hours. “Given the inherent interaction we had with the general public, safety was on our minds from Day 1,” he says. During the project’s more than 115,000 work hours, the project recorded no lost-time incidents.

Back to "35 Best Projects Showcase Midwest Design, Construction Innovation"

Post a comment to this article

Report Abusive Comment