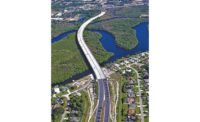

SR 679 (Pinellas Bayway) Structure E Design-Build

Tierra Verde, Fla.

Best Project, Highway/Bridge

Submitted By: American Bridge Co., a Southland Holdings Co.

Owner: Florida Dept. of Transportation, District 7

Lead Design Firm: American Consulting Professionals

General Contractor: American Bridge Co., a Southland Holdings Co.

Structural Engineer: Kisinger Campo & Associates Corporation

Subcontractors: EPG Engineering, F.R. Aleman & Associates, Harbor Coordination Solutions, Hyatt Survey Services, Intera, L.A. Design, Element Engineering Group, Tierra

When the American Bridge team was awarded the $56.8-million design-build contract to build its replacement, the original Pinellas Bayway bridge had reached the end of its useful life and had no dedicated multimodal capacities—and was often stuck open or closed.

The new, two-lane, 2,583-ft bridge over the intracoastal waterway will fix those issues, including providing a 12-ft-wide shared-use path to give pedestrians safe access between Isla Del Sol and Tierra Verde islands.

To complete that work in a congested area, American Bridge had more than 70% of precast elements delivered by water, helping to reduce the number of required temporary trestles by 75%, and with an active and interested community, held weekly “coffee talks” to connect with residents and businesses.

That move, and cutting down on temporary trestles to cut down on environmental impacts, led one judge to score the project higher.

The Florida Dept. of Transportation (FDOT) awarded the design-build contract in June 2018, with work wrapping up on the bridge in May 2022. The bridge is founded on precast piles with water-level foundations featuring architectural columns and caps, with Florida I-Beam girders, cast-in-place decks, barrier walls and a fender system completing the structural work.

Photo courtesy American Bridge Co.

Apart from the bridge, the project team resurfaced 1.7 miles of SR 679 and constructed a roundabout, lighting, signage, an Intelligent Transportation System package and retention ponds. The existing bascule bridge was removed via explosive and piece-by-piece demolition.

The largest challenges, according to the project team, were the environmental impacts to residents, motorists, anglers and cyclists; and building so close to the existing bridge, while tying into nearby interchanges with the grade, while maintaining the 65-ft clearance over the channel.

The American Bridge team reduced the temporary trestle by more than 75% from concept plans to minimize temporary seagrass impacts and reduced the overall bridge length and increased span length to lessen pier structures, bearings and expansion joints, minimizing the long-term maintenance cost.

Two-stage, cast-in-place walls met both required project aesthetics and traffic phasing, while deep foundations reduced the potential for cracking due to settlement, and other aspects helped to extend the bridge’s lifespan beyond the 75-year design life requirement. To maximize that lifespan, American Bridge used a glass fiber reinforced polymer rebar in the seawalls. It doesn’t corrode, and seawall caps will remain highly serviceable for FDOT.

The project team also worked to meet the community and FDOT’s vision, including shortening the bridge by almost 300 feet and lowering the profile, and providing a more symmetrical and aesthetically pleasing view for mariners traveling through the channel, residents and visitors to Fort DeSoto Park.

Post a comment to this article

Report Abusive Comment