It’s not often easy to be first. But that hasn’t stopped an intrepid adventurer from going against the prevailing winds of structural practice to debut a dynamic shift in skyscraper engineering that at minimum promises improved tall-building resilience and sustainability—at a reduced cost. The first proof-of-concept for the radical technique, called performance-based wind design, is stirring up a storm of optimism for tall-building enthusiasts committed to advancing “real” not “cookbook” engineering. And they predict that in 10 or 15 years, high-rise PBWD will be the norm the world over.

PBWD is hailed as “transformative” by the structural engineer premiering the approach on a 671-ft-tall project in Austin. “The first implementation of PBWD on a real project is a significant step forward for the industry to demonstrate the viability and benefits of the technique,” says Sean P. Clifton, senior principal for Magnusson Klemencic Associates (MKA), the structural engineer that sold the novel strategy to the codevelopers of the Austin tower, under construction since January.

PBWD is the “future” for towers 400 ft or taller, Clifton adds. To encourage other high-rise designers to follow in its footsteps, the team for the 58-story 321 West 6th Street job is sharing its lessons learned.

The technique is the rigorous evaluation of explicit performance objectives for occupant comfort, serviceability and safety. As with the established performance-based seismic design (PBSD) for tall buildings, the wind engineering method minimizes materials and reduces the carbon footprint compared to a cookbook design.

The 561,000-sq-ft building, with parking at the base topped by an office block and a residential tower (rendering, left), has a relatively simple geometry, which made it a good candidate for the first PBWD high-rise.

Rendering courtesy Handel Architects/Neoscape

PBWD can also increase leasable space or shrink the building’s footprint. And it has the potential to reduce the volume of foundation materials and shorten the construction schedule.

As a first example, the Austin design was intentionally conservative. Clifton predicts twice the savings or more on future towers. Further honing of the technique could reduce carbon by 12% or greater using structural optimization alone—without mining the embodied carbon content of the materials themselves. It all depends on the building, its location and a fine-tuning of PBWD.

the 561,000-sq-ft Austin tower, PBWD reduced the cost of the reinforced concrete structure by 5% and reduced embodied carbon by 6%, compared with the conventional design MKA executed in parallel, in case the PBWD didn’t pan out.

Courtesy ASCE

Unlocking Engineering Freedom

“While some might say performance-based seismic design, wind design and structural fire design are the most important developments in structural engineering in the last century, I believe the most important development is the courage and tenacity of today’s structural engineers to venture beyond the prescriptive limits of the building code. With the sound underpinning of science and physics and a return to the first principles of engineering, a whole new generation of more resilient and sustainable buildings is coming. It is truly an exciting time working with these new freedoms we have unlocked!”

— Ron Klemencic, 2018 ENR Award of Excellence Winner

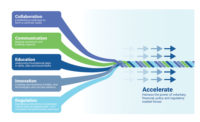

Engineers predict PBWD will, in 10 or 15 years, replace prescriptive design and static wind tunnel design for high-rises, thanks to the prestandard and the first PBWD structure underway in Austin.

Image courtesy MKA.

*Click on the image for greater detail

The appearance of the structure of a performance-based wind design is no different from that of a prescriptive design. Either way, the Austin tower would have a reinforced concrete shear-wall core with outriggers to perimeter columns (blue).

Image courtesy MKA.

*Click on the illustration for greater detail

The technique trimmed the volume of concrete in the core’s shear walls by 1,800 cu yd, or 5%, of the total concrete volume. It also shaved 6 in. off the core walls’ 3-ft thickness. PBWD cut 350 tons, or 10%, of the reinforcing steel and 125 tons, or 250%, of the embedded steel beams in the core, which will contain only 50 tons.

MKA hopes the Austin example will trigger a trend. Competitors choosing to follow its lead will not only provide “a more-efficient design for their clients, they will substantially reduce embodied carbon,” says MKA’s chairman and CEO Ron Klemencic. He also is the 2018 ENR Award of Excellence winner for energizing an era of collaborative R&D to advance building quality, safety and speed, as a director of the Charles Pankow Foundation for building research (ENR 4/19-16/18 p. 34).

Long before net-zero carbon was on the horizon, PB design was important to Klemencic. “The commercial implementation of PBWD marks the next major milestone in returning structural engineering to the practice of science, physics and math, as opposed to blindly following prescriptive code requirements,” he says.

Klemencic predicts that in a decade, PBWD will be the standard of care for tall buildings in regions of high wind demand. The impact on the built environment will be tenfold or more than that of PBSD, he says.

Viral Patel, director of design for structures at Walter P Moore (WPM) and the Austin tower’s structural peer reviewer, thinks PBWD will be the “standard way of engineering tall buildings in 10 to 15 years.”

Computational simulation shows the wind flow slowing as it approaches the face of the building (green and blue lines right), the faster flow around the corners (red and yellow) and the turbulent wake behind the building.

Graphic courtesy CPP

Challenges Remain

Challenges remain, but there is potential to improve the process and “definitely money to be saved,” Patel says. “The first time there was a learning curve,” he adds.

The Austin example would never have gained traction were it not for the building’s developers. In pitching the idea, MKA had estimated a 5% to 10% reduction in the cost of structural materials. But without a precedent, there was no guarantee of any savings.

“We felt the payoff was worth the risk,” says David Knoll, vice president of real estate for the Ryan Cos., the general contractor for the Austin job and codeveloper with Tishman Speyer.

MKA is known to Tishman Speyer, which developed the engineer’s first PBSD building in San Francisco. In Austin, “we are pleased” with the outcome and would go down the PBWD path again, says Cynthia Bowden, senior director in Tishman Speyer’s design and construction group.

There is a caveat: Tishman Speyer would only consider a PBWD with MKA or its equal and the same consultants for wind engineering and peer reviews.

Tishman Speyer and Ryan decline to provide development or construction costs on the Austin project, though they say the thinner core walls reduced the building’s footprint by 1 ft on all sides, which saved on cladding.

The developers also think PBWD might trim the schedule because there is less material to put in place. But with only excavation complete, it is too soon to tell. They will know well before the phased substantial completion set for late 2024 and early 2025.

MKA did the structure’s parallel prescriptive design on its own dime. But even without that fee, there is a cost premium for PBWD since the effort is an order of magnitude greater.

PBWD requires more hours for analysis, more in-depth wind tunnel tests and both structural and wind design peer review. There are volumes of data to sift through to make sure the acceptance criteria are met and it takes a long time to perform the analysis.

Set into a model of downtown Austin, 321 West 6th Street is, to date, the only PBWD tower tested in CPP’s wind tunnel.

Photos courtesy CPP

Still, the technique more than pays for itself, says MKA. Even on the Austin tower, the construction cost reduction is more than ten times the added design expense, says Clifton.

The architects for the tower—which stacks parking decks at the base topped by an office block followed by an apartment section on top—also support PBWD for its benefits to the architecture. “It’s really something to embrace,” says James Hakes, a principal of Handel Architects, the tower’s designer. “There’s no reason to be afraid of it,” especially with a firm like MKA, he adds. “Working with innovative engineers gives us more opportunity to do innovative architecture.”

Brandon Townsend, a principal for the architect-of-record, Page, says the approvals process with MKA and city building officials was so successful that Page and MKA are pursuing PBWD on a 750-ft-tall Austin project.

321 West 6th Street is not only the first PBWD tower approved and under construction; it is the first tall building designed, approved and permitted according to the precepts of the Prestandard for Performance-based Wind Design, published by the American Society of Civil Engineers’ Structural Engineering Institute (ASCE-SEI) in 2019, with support from the Pankow foundation, the MKA Foundation and other groups.

The concept of PBWD is not new, but the prestandard for the first time presents a format that structural engineers and building officials can follow, says John Kilpatrick, a member of the prestandard committee and practice area lead in RWDI’s wind engineering group.

RWDI is the peer reviewer for the Austin job’s wind specialist, CPP Wind Engineering Consultants. The prestandard allows “a site-specific wind climate analysis if you use approved statistical techniques,” adds Roy Denoon, CPP’s senior principal and a committee member.

The document is important, adds Patel, a prestandard peer reviewer. Otherwise, “many engineers could misuse” the process, he says.

Rather Than Reinvent The Wheel

Rather than reinvent the wheel, the creators of the prestandard used the template of the well-established ASCE-SEI tall-building PB seismic design standard.

Starting about 25 years ago, MKA executed its first PBSD towers without any guides or standards. “For better or worse, we just started doing it,” says Klemencic.

In the absence of an accepted methodology, the PBSD pioneer was put through the wringer by reviewers and cautious building officials in California. “A lot of tears were shed over the uncharted course of peer review, process and technology,” says Klemencic. “It was tough.”

The review and approval process improved considerably after the first guidelines came out about a dozen years ago, written based on knowledge gleaned from first-hand experience and the results of laboratory tests of structural members under earthquake loads. Today, PBSD is the norm for tall buildings throughout the world.

“Witnessing first-hand the dramatic positive impacts of PBSD, PBWD is poised to have an even greater and broader impact,” says Klemencic.

The ordeal in the early years of PBSD informed MKA’s polar-opposite strategy to initiate PBWD: “Avoid the bloodshed,” Klemencic says, by engaging the community of peer reviewers and competitors to write the methodology in advance of executing the projects.

Consequently, without a real-world example or any research into the subject, MKA approached ASCE to discuss engaging its already established wind subcommittee for its design load standard, called ASCE 7. The wind engineer and peer reviewers for the Austin project, plus MKA’s wind and seismic subject matter experts, all had a hand in writing or reviewing the prestandard.

In hindsight, with the Austin project under MKA’s belt, Klemencic regrets his “cart before the horse” strategy for PBWD. Without built examples to follow, the prestandard contains unclear rules and is more limiting than it needs to be, he says. And he is concerned it will be difficult to revise in any substantive way.

The guidelines are largely written around the common reinforced concrete structure with shear wall cores to resist lateral loads, similar to the Austin building. Design freedom lies in other lateral systems, for example steel-braced cores and megaframes, says Klemencic.

“The essence of performance-based design has eroded,” Klemencic adds. “PBWD today is no more than enhanced prescriptive design with a different set of rules.”

Research, such as at Washington State University on steel-reinforced link beams (above) and at UCLA on reinforced concrete link beams (below), will advance PBWD.

Photo (above) by Christopher Motter/WSU; Photo (below) by Saman Abdullah/UCLA

Define the Desired Outcome

In PBWD, engineers define the desired outcome or achievement, taking into account life safety, creature comfort and building performance. Then, they demonstrate the design meets the desired outcome.

“Instead of applying a force and calculating displacement, we target an acceptable level of displacement and from there calculate forces, stresses, strains and more,” Klemencic explains. That accounts for much of the material savings in the shear-wall core’s lateral system.

The prestandard guides engineers to the outcome by outlining major design innovations for wind resistance. These include nonlinear dynamic analysis for wind design, limited inelasticity in specified elements of the main wind force-resisting system, system-based performance criteria and enhanced design criteria for the building envelope.

Inelastic behavior has long been the accepted approach in seismic design—even before PBSD—but not in wind design. For PBWD, the analysis for inelastic behavior is more complicated because windstorms can last for hours. Earthquakes last only 10 to 30 seconds.

But in a major departure from prescriptive wind requirements, PBWD uses nonlinear response-history analysis to assess inelastic behavior rather than linear analysis to assess elastic, or bounce-back, behavior.

For example, in the two most severe loading scenarios, which are a windstorm likely to occur once every 700 years or 1,700 years, PBWD allows some acceptable nonlinear response, or permanent deformation, of the reinforcing steel or structural steel due to building displacement or drift. The minor amount of yielding does not in any way compromise life safety, says MKA.

PBWD involves applying actual dynamic wind loads instead of prescribed static loads to the building model in the wind tunnel, which offers a more realistic picture of the building’s behavior under wind. “It allows members that can accommodate inelastic behavior to push the limit,” says WPM’s Patel.

Properly implemented, the prestandard, available free of charge, results in buildings capable of achieving wind performance objectives specified in ASCE 7, and in many cases, superior performance, according to ASCE.

The Austin tower team is not only following the pre-standard, it is recommending improvements based on its experience. A version 1.1 is expected by early fall. A standard could be out in 2025, says ASCE.

The prestandard outlines a process for review and approval that was helpful in Austin. The group met four times during the design phase to review: 1) the basis of design; 2) wind tunnel testing and wind loading recommendations; 3) initial proportioning, computer modeling and initial design; and 4) inelastic modeling and design.

Collaboration is Almost Enjoyable

The prestandard’s required design-phase engineer-reviewer collaboration is “almost enjoyable,” says RWDI’s Kilpatrick, compared to the often contentious process that typically kicks in after the design is set in stone, when changes are more difficult.

During the Austin peer review meetings, there was a lot of debate and discussion, but issues got resolved, Kilpatrick says. “If we can get two wind consultants to agree, everyone feels better.”

The prestandard provides three methodologies for PBWD. For the Austin project, MKA selected the first, which is the simplest.

The PBWD and the parallel design look no different. The lateral force-resisting system consists of reinforced concrete shear walls placed around the elevators and fire exit stairs, supplemented with a single-level concrete-wall outrigger system that connects to perimeter columns, about two-thirds up the height of the tower.

Floor slabs in the apartments are post-tensioned. Floors in the office and parking levels have post-tensioned beams and slabs. Perimeter columns slope at the amenity levels between the more slender residential tower and the broader office block. Two subgrade parking levels are underlain by concrete drilled shafts into limestone.

MKA’s Clifton pushed for PBWD on the Austin structure because of its relative simplicity. “We see benefits for a more complex structure but it adds a level of complexity” to the engineering, he says.

MKA began working on the Austin tower in early 2021, about three years after it had started doing some in-house studies of PBWD.

In April 2021, “MKA raised their hand and walked us through the benefits and risk mitigation” for the novel method, says Ryan’s Knoll.

With only the excavation complete, developers say it is too soon to tell whether there will be construction schedule savings associated with PBWD.

Photos courtesy Ryan Cos.

Biggest Risk

A big unknown was whether the structural review would delay what Page’s Townsend calls a “very aggressive” design schedule—nine months instead of a more-comfortable year. But the review did not take any longer than reviews for previously submitted high-rises, according to the city’s building officials.

In May 2021, during schematic design, MKA reached out to the city and invited members of its Development Services Dept. (DSD) to attend an initial peer review kickoff meeting.

The city approved the structure under the section of the building code that allows for alternative materials, design and methods of construction and equipment, and under the code’s analysis section, which allows for a rational structural analysis that takes into account equilibrium, general stability, geometric compatibility and both short- and long-term material properties, in accordance with well-established principles of mechanics.

As a condition of PBWD, the city requested approval letters from the peer reviewers, confirming that the lateral design procedures used were in general conformance with ASCE’s recommendations and its PB design guidelines.

The ongoing collaboration between the design and peer review teams, in tandem with periodic check-ins with the city, allowed the city’s structural reviewers to have “a level of familiarity and understanding of project-specific design processes” not typical of other projects and associated plan reviews, according to DSD.

The city also says it “highly encourages” design teams considering PBWD and any other PB design “to engage the local building official/authority having jurisdiction early and confirm any requirements they may have for alternate methods of compliance.”

Beyond peer review, PBWD requires different and more in-depth wind tunnel tests to provide more specific wind force data to the design engineer.

Traditionally, in a wind tunnel test, equivalent static loads are applied to the structure, not dynamic loads. In the prestandard, only the framework is prescribed. The design itself can be fairly fluid “once you understand what can behave in a nonlinear way,” RWDI’s Kilpatrick says.

The prestandard allows a site-specific wind-climate analysis if approved statistical techniques are used. Wind-loading time histories are used in PBWD to look at nonlinear behavior of certain elements.

The Austin tower was the first building to go through this process in the CPP wind tunnel. RWDI has not yet had a PBWD tower in its tunnel. Neither firm knows of any other PBWD towers under construction.

ASCE 7-10 is the governing standard in Austin, but the design team got permission to use ASCE 7-16’s 700-year recurrence wind speed, which is 108 mph, not 115 mph. “It would have been more difficult to get permission had it been a prescriptive design,” says CPP’s Denoon.

There is an advantage to reduced wind speeds. “If there is a 10% reduction in wind speeds, there is a 20% reduction in pressure,” he adds.

The developers have confidence in the PBWD, but “are interested to see how the building performs and if you can tell a difference in the sway or drift,” says Tishman Speyer’s Bowden.

In response, MKA says design objectives include occupant comfort for one- and 10-year wind occurrences; operational performance for the 10-year wind and continuous occupancy for the 700-year wind.

from the first PBWD effort include a need to better manage the volumes of data generated, custom software and more-powerful computers. MKA’s initial continuous analysis lasted one month, which threatened the design schedule. Faster computers purchased cut the time by one third to one half.

MKA says more research is needed to determine how much nonlinear response should be allowed in different types of link beam reinforcement. The results of tests underway will shed light on better detailing, including the behavior under wind loading of steel-reinforced link beams and link beams with steel embeds.

Klemencic is excited to see PB design maturing and envisions a time when a mix of the three PB approaches—seismic, wind and PB structural fire design, in part to eliminate the need for applied fire resistance on structural steel—provides even better buildings.

He says, “PB design opens up a huge range of opportunities for research, development, design and implementation—all resulting in a better, safer, more resilient and lower-carbon future.”

Post a comment to this article

Report Abusive Comment