JOC Program Line-item Estimating

Job Order Contracting

SEPTEMBER 21, 2022

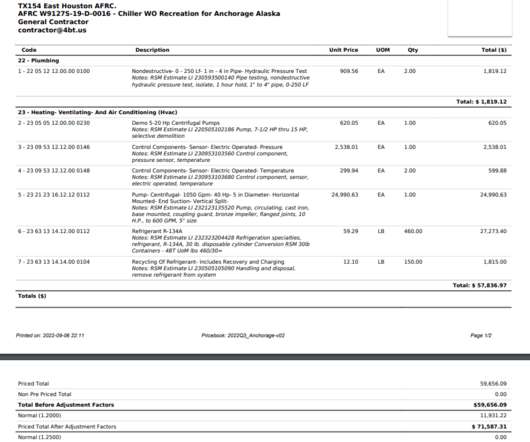

. • NEVER accept a lump sum estimate for a workorder/project without a full detailed line-item estimate and review of line-times and quantities. Fully audit cost estimate and actual cost information. The post JOC Program Line-item Estimating appeared first on 4BT. Verify all aspects of the direct work (e.g.,

Let's personalize your content