Making cement manufacturing more efficient

GCP Applied Technologies

NOVEMBER 29, 2019

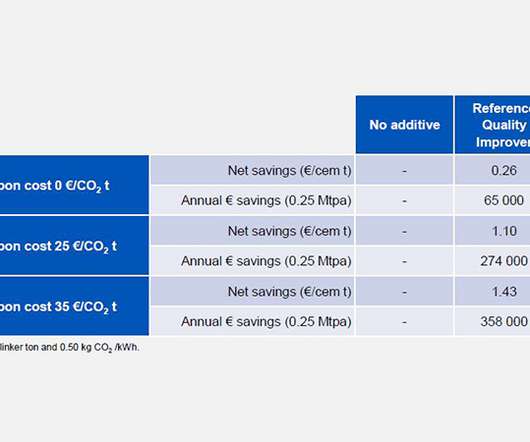

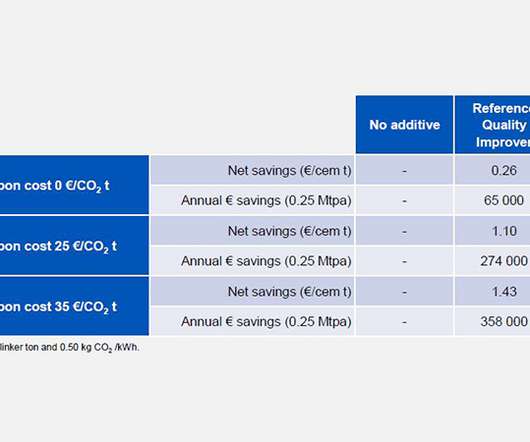

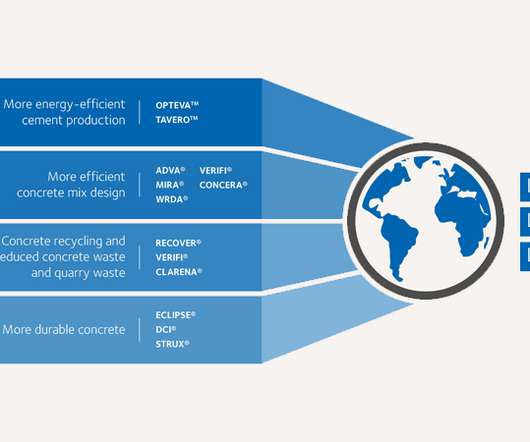

From concrete production to general contracting, there is a growing focus around the world about the need to reduce our carbon footprint. The increased awareness of CO 2 emissions from cement production has brought focus on techniques that improve sustainability. Grinding aids and quality improvers can reduce emissions.

Let's personalize your content