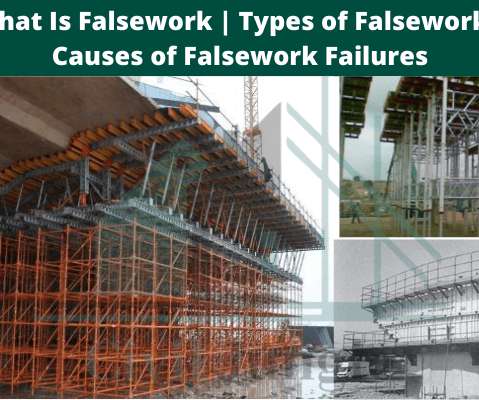

What Is Formwork Failure | Causes of Formwork Failure

CivilJungle

DECEMBER 22, 2019

What Is Formwork Failure? The construction of a concrete building needs formwork to support. Specific forms are engineered structures that are necessary to support loads like construction materials, fresh concrete, equipment, workers’ movement load, various impacts, and also wind pressure.

Let's personalize your content