LEAN Job Order Contracting Best Management Practices

Job Order Contracting

MAY 22, 2018

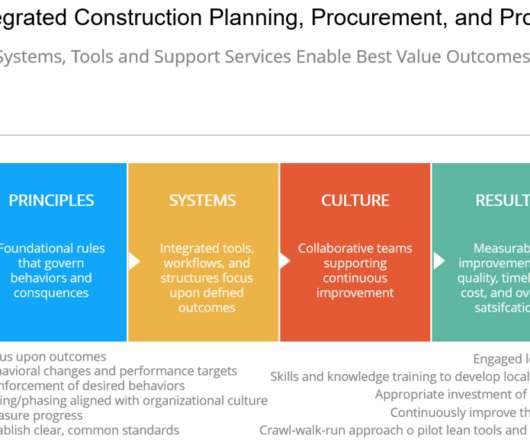

LEAN Job Order Contracting best management practices are critical to assuring optimal outcomes for owners, building users, and construction contractors. Job Order Contacting (JOC) is a competitively bid, firm fixed price and indefinite quantity constriction delivery method and contract. Concrete pavement repair. Re-lighting.

Let's personalize your content