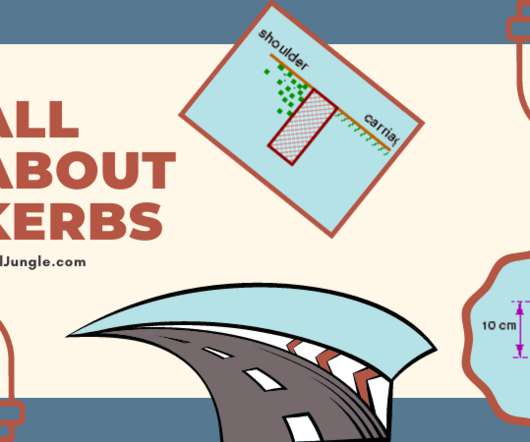

Kerbs In Roads | Types of Kerbs | Shape of Kerbs | Materials of Kerbs in Roads | Kerb Height | What Is Kerb Stone | Materials of Kerb Stone | Road Kerb Details

CivilJungle

FEBRUARY 7, 2021

Kerbs In Roads: The top of the kerbs should be 100 mm above the road surface. With the pavement , the kerb is laid on a concrete bed of at least 100 mm thickness. To the concrete level, kerbs can be tapped. This type of kerns is generally used in flat roads or areas. By the paving machine, the asphalt kerb is made.

Let's personalize your content