Feasibility For Machine Guarding Is A Big Deal For Employers and Employees

FDR Safety

MAY 13, 2024

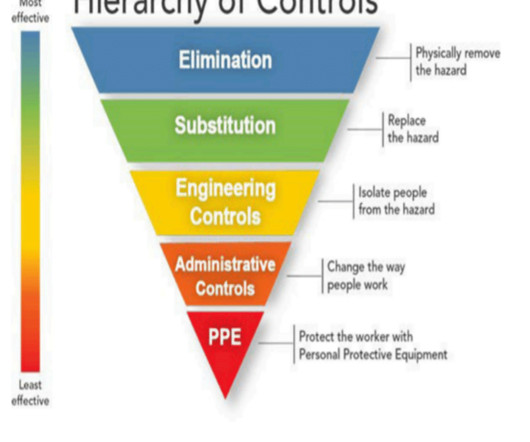

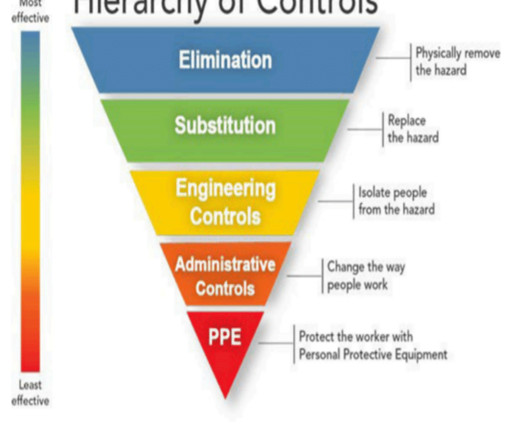

Finding safeguards for a specific task is challenging because a physical guard may not be feasible. This article is intended to introduce you to a long-accepted concept recognized in OSHA and ANSI standards but is not well known or understood. All machinery contains hazards, and some level of residual risk.

Let's personalize your content