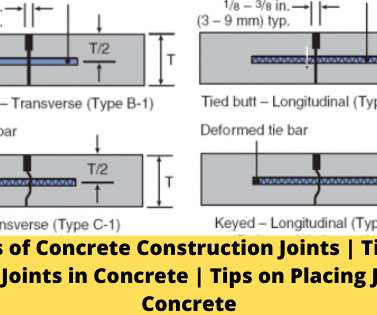

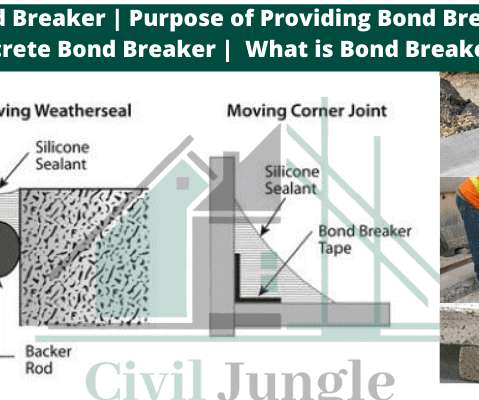

Types of Concrete Construction Joints | Tips on Placing Joints in Concrete | Tips on Placing Joints in Concrete

CivilJungle

FEBRUARY 27, 2020

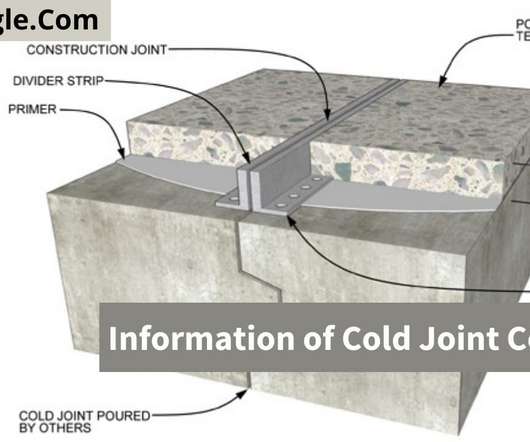

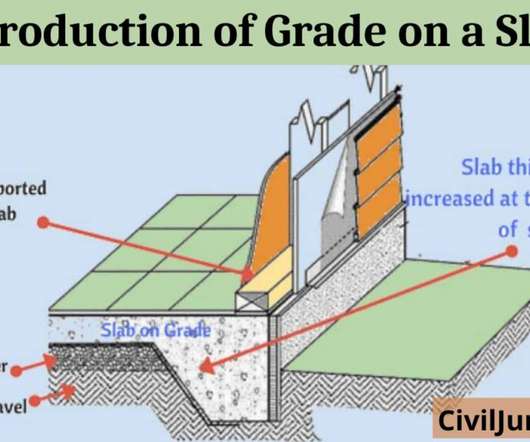

Concrete joints are used to compensate when concrete expands or shrinks with changes in temperature. Concrete joints are normally used to prevent cracking when concrete contractions, creating training, tools, sawdust, and placement of joint builders.

Let's personalize your content