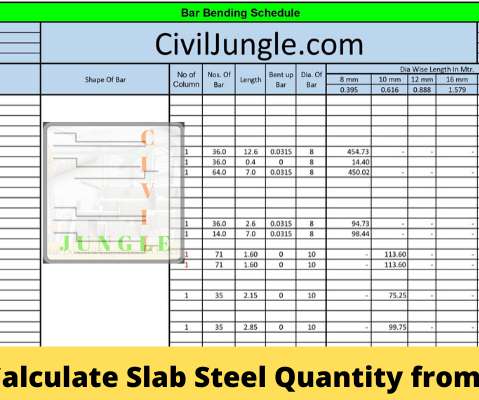

How to Calculate Slab Steel Quantity from Drawing

CivilJungle

JUNE 27, 2020

For cutting and bending purposes, schedules should be provided as separate A4 sheets and not as part of the detailed reinforcement drawings. • The form of bar and fabric schedule and the shapes of the bar used should be in accordance with BS 8666. • Bar Bending Schedule Required Ment Data. Slab Beam. x d)) +Lap.

Let's personalize your content